FL Series Fluidized Granulator

FL Series Fluidized Granulator( Fluid Processor)

Preface

YIBU” considers that Fluidized Granulating is an organic combination of mechanical design and manufacture technology. Therefore hundreds of Granulating machines either for China or exported to USA, Japan, Indonesia, Iran and many other countries are designed in accordance with the process of raw materials.

We have manufactured decades specifications and 150 different machines to meet different needs. These practical experiences will be very beneficial to customers.

Principle

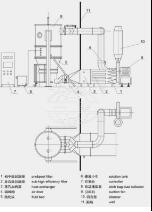

The powder granule in vessel (fluid bed) appears in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive is sprayed into the container. It makes the particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

Equipment&Process

7.For the machine ,we have CIP and WIP for customer to choose .

- Pharmaceutical industry : tablet capsule , Low sugar or no Sugar granule of Chinese traditional medicine .

- Foodstuff :cocoa ,coffee ,milk powder ,juice of granulate ,flavoring and so on .

- Other industries: pesticide ,feed ,chemical fertilizer ,pigment ,dyestuff and so on.

- Drying : Power or granule state of wet material .

- Coating : Protection layer ,color , controlled release ,film,or bowels solved coating of granules and pills

Technical Parameters

|

Spec

Item |

FL |

|||||||||||||||||||||

|

3 |

5 |

15 |

30 |

60 |

120 |

200 |

300 |

500 |

1000 |

|||||||||||||

|

Vessel |

Volume |

L |

12 |

22 |

45 |

100 |

220 |

420 |

670 |

1000 |

1500 |

3000 |

||||||||||

|

diameter |

mm |

300 |

400 |

550 |

700 |

1000 |

1200 |

1400 |

1600 |

1800 |

2200 |

|||||||||||

|

Capability |

min |

kg |

1.5 |

4 |

10 |

15 |

30 |

80 |

100 |

150 |

250 |

800 |

||||||||||

|

max |

kg |

4.5 |

6 |

20 |

45 |

90 |

160 |

300 |

450 |

750 |

1200 |

|||||||||||

|

Fan |

velocity |

M3/h |

1000 |

1200 |

1400 |

1800 |

3000 |

4500 |

6000 |

7000 |

8000 |

13670 |

||||||||||

|

pressure |

mmH2o |

375 |

375 |

480 |

480 |

950 |

950 |

950 |

950 |

950 |

1400 |

|||||||||||

|

power |

kw |

3 |

4 |

5.5 |

7.5 |

11 |

18.5 |

30 |

37 |

45 |

90 |

|||||||||||

|

Steam consumption |

Kg/h |

15 |

23 |

42 |

70 |

141 |

211 |

282 |

366 |

451 |

750 |

|||||||||||

|

Compressed air consumption |

M3/min |

0.9 |

0.9 |

0.9 |

0.9 |

1.0 |

1.0 |

1.1 |

1.5 |

3.0 |

4.0 |

|||||||||||

| Weight of the main body | kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2500 | 3500 | |||||||||||

| Steam pressure | Mpa | 0.1~0.4 | ||||||||||||||||||||

| Temperature | ℃ |

Adjustable at the range of room temperature to 120℃ |

||||||||||||||||||||

| Working time | min |

45~90min, but depending on the property of the raw material itself |

||||||||||||||||||||

| Collect rate | % | ≥99 | ||||||||||||||||||||

| Noise | dB(A) |

Noise≤75dB(A) the main machine should be installed seperately from the fan. |

||||||||||||||||||||

|

Dimensions of main machine |

m |

1.0* 0.6* 2.1 |

1.2* 0.7* 2.3 |

1.25 *0.9 *2.5 |

1.6* 1* 2.5 |

1.85* 1.4* 3 |

2.2* 1.65* 3.3 |

2.34* 1.7* 3.8 |

2.8* 2.0* 4.5 |

3* 2.25 *5.0 |

4*2.8 *7.2 |

|||||||||||

Options

Product charging by lifting machine.

Product charging by vacuum transfer system

Printer

WIP system

-

FL Series Fluidized Granulator

-

FL Series Fluidized Granulator

-

FL Series Fluidized Granulator

-

FL Series Fluidized Granulator

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow