FWD Series Multi-functions filter washing drying machine

Product summary

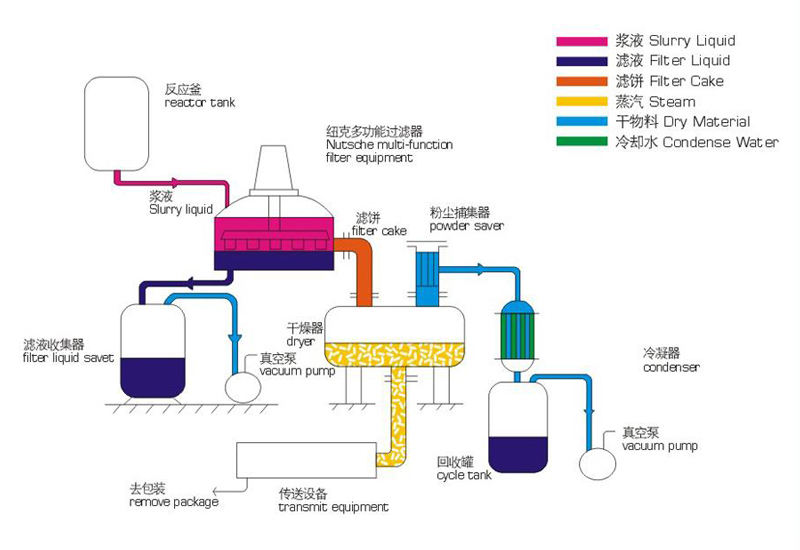

The Filter- washing - drying "three in one" is a new generation of solid-liquid separation process equipment newly -promoted by home and abroad.

The Multi-function filter washing and drying Equipment can make the material to complete the filtering ,washing and drying process in a closed container equipment.Maximize the improvement of equipment utilization.

It avoids the pollution of the environment, and also avoids the pollution of the environment to the material, reduces the loss of material transfer, saves the amount of solvent used, and is suitable for intermittent batch production.

Application field

Filtering purposes:to filter crystalline or granular materials, liquids required, to wash required solid materials, and dry required solid materials.

Application industry:biopharmaceutical, food , fine chemical , electronics , printing and dyeing industry.

Applicable materials:antibiotics, penicillin, proteins, polymers, vitamins, citric acid, pigments, sugar ,Titanium dioxide , melamine , chlor-alkali and so on industry production.

Working principle

Filtering

Feed the solid-liquid mixture slurry produced by the upstream reactor or crystallization equipment into the tank of the three-in-one equipment, and use the pressure difference as the driving force to realize the filtration and separation of the solid-liquid mixture.Practical applications include pressure filtration, vacuum filtration, and combined pressure and vacuum filtration.Pressure filtration uses clean compressed air, nitrogen or other inert gases.According to practical experience, general products in the pharmaceutical industry can be filtered with a pressure of 0.2-0.3MPa.Some products in the chemical or food industry require higher filtration pressure, and some pressure reaches 1.0MPa.

Washing

After the filtration process is completed, the next step of process operation is required, that is washing.The three-in-one equipment tank is equipped with a special spray device, which can make the cleaning (washing) liquid evenly distributed in the tank.By turning on the stirring system, stirring lifting mechanism, and transmission mechanism, the blades can be rotated and moved up and down axially, so that the materials can be fully washed and the impurities adhered to the surface of the crystal grains can be cleaned.The washing liquid used for washing and the number of washing times shall be determined according to the characteristics of the material and production process.

Drying

The drying process of the three-in-one equipment can be vacuum drying.The main factors affecting the vacuum drying process are the degree of vacuum, drying time, and the characteristics of the stirring paddle.The vacuum drying process is to use a vacuum system to pump out the inert gas in the tank to reduce the number of gas molecules and isolate the air.

It is mainly suitable for materials that are easy to oxidize and deteriorate, and is also suitable for materials that need to recover solvents and heat-sensitive materials for evaporation.In vacuum state, it can reduce the chance of material contamination, or inhibit the growth of some bacteria, so it is especially suitable for drying sterile materials.

● Material discharge

The dry material is automatically discharged from the side outlet through the reverse of the S-type stirring paddle.

Product characteristics

● System closed

This equipment is a fully enclosed operating system, which can completely avoid the air pollution caused by solvents in the production process, and at the same time , it can reduce the occurrence of poisoning accidents caused by contact with toxic substances.

● Recycling completely

Materials and solvents are almost completely recovered, avoiding waste caused by material omission and solvent volatilization, which has great economic benefits, especially when the value of materials and solvents is high.This is especially true when handling materials and using solvents with high value.

● Drying at the same time

The Filtering washing and drying can be done in the same equipment.

The vessel walls can be equipped with heating jackets to enable dry operation.

● Continuous Operation

It enables filtration and drying to be carried out in one continuous system without handling wet filter cake.A drier can be connected under the filter, so that the wet filter cake can be directly unloaded into the drier, and the dried product can be mechanically transferred to the weighing and packaging sections.

● Save Manpower

A non-technical person who has undergone simple training can complete the operation. For the procedures on Start,Stop ,Automatic feeding and discharge, it no need technical personnel to do it .

● Clean thoroughly

Due to the automatic spraying and re-beating functions of this equipment, the filter cake can be cleaned very thoroughly.And the amount of washing liquid is less than that of other types of equipment, which can reduce sewage discharge and waste water treatment costs.

● Cleaner production

This multifunctional filter drying system is equipped with a dust collector, which can completely collect the dust generated after drying, and can meet the production operation requirements of high cleanliness.

Technical parameter

|

Spec |

Filtering area (㎡) |

Inner Diameter of barrel (mm) |

Equipment Volume (m³) |

Filter cake height (mm) |

Paddle lifting height (mm) |

Power(kw) |

Net weight (t) |

Total Height (mm) |

|

FWD-500 |

0.19 |

500 |

0.15 |

140 |

160 |

2.2 |

1.5 |

3000 |

|

FWD-600 |

0.28 |

600 |

0.22 |

180 |

200 |

2.2 |

1.7 |

3300 |

|

FWD-800 |

0.5 |

800 |

0.46 |

200 |

220 |

3 |

2.25 |

3500 |

|

FWD-1000 |

0.8 |

1000 |

0.95 |

220 |

250 |

5.5 |

3.5 |

3800 |

|

FWD-1200 |

1.0 |

1200 |

1.2 |

250 |

300 |

7.5 |

4.9 |

4000 |

|

FWD-1400 |

1.5 |

1400 |

1.9 |

300 |

350 |

11 |

6.5 |

4500 |

|

FWD-1600 |

2.0 |

1600 |

2.6 |

300 |

350 |

15 |

7.5 |

4500 |

|

FWD-1800 |

2.5 |

1800 |

3.2 |

350 |

400 |

15 |

10 |

4700 |

|

FWD-2000 |

3.0 |

2000 |

4.5 |

400 |

450 |

18.5 |

11.7 |

5100 |

|

FWD-2300 |

4.0 |

2300 |

6.4 |

400 |

450 |

22 |

12.8 |

5200 |

|

FWD-2600 |

5.3 |

2600 |

9.0 |

400 |

450 |

22 |

17 |

5600 |

|

FWD-2800 |

6.0 |

2800 |

10.5 |

450 |

500 |

30 |

21 |

5800 |

|

FWD-3000 |

7.0 |

3000 |

12.0 |

500 |

550 |

37 |

24 |

6000 |

-

FWD Series Multi-functions filter washing drying machine

-

FWD Series Multi-functions filter washing drying machine

-

FWD Series Multi-functions filter washing drying machine

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai