SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

(CE Certificate) (Pattent)

Product Description

SZG Series Conical Vacuum dryer (Vacuum Double cone dryer ) (Rotary conical vacuum dryer) (RCVD Dryer)is a new generation drying device developed by our factory on the basis of combining the technology of similar equipment. It has two connecting ways, i.e. belt or chain. Therefore it is stable in operation. The special design guarantees two shafts realize good concentricity. Heat medium and vacuum system all adapt reliable rotating connector with the technology from USA. On this basis, we also developed SZG-A. It can carry out steeples speed change and constant temperature control.

As a specialized factory in drying industry, we supply hundred sets to the customers every year. As for working medium, it may be thermal oil or steam or hot water. For drying the adhesive raw material, we have designed specially a stirring plate buffer for you.

Principle

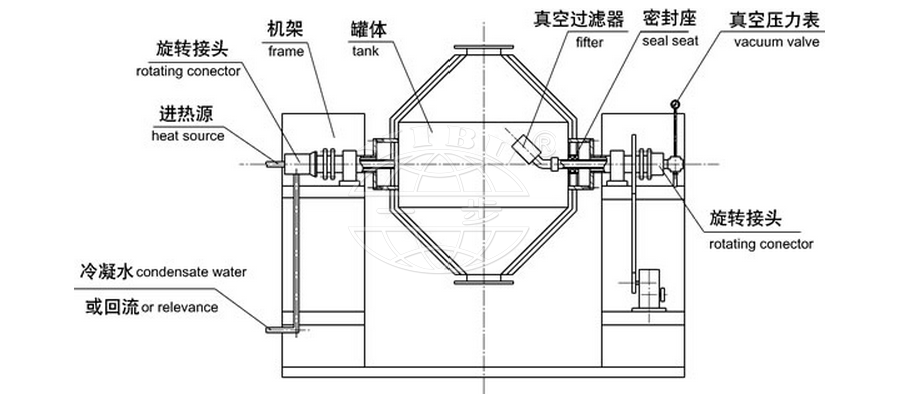

As a specialized company in drying industry, we supply hundred sets to the customers every year. As for working medium, it may be thermal oil or steam or hot water. For drying the adhesive raw material, we have designed specially a stirring plate buffer for you. The biggest may be 8000L. Let heat source (for example, low pressure steam or thermal oil) pass through the sealed jacket. The heat will be transmitted to raw material to be dried through inner shell;Under driving of power, the tank is rotated slowly and the raw material inside it is mixed continuously. The purpose of reinforced drying can be realized; The raw material is under vacuum. The drop of steam pressure makes the moisture (solvent) at the surface of raw material reach the state of saturation and evaporate. The solvent will be discharged through vacuum pump and recovered in time. The inner moisture (solvent) of raw material will infiltrate, evaporate and discharge continuously. The three processes are carried out unceasingly and the purpose of drying can berealized within a short time.

Schematic of the structure

Features

1.When oil is used to heat, use automatic constant temperature control. It can be used for drying biology products and mine. Its temperature of operation can be adjusted form 20-160 ℃ .

2.Compared to ordinal dryer, its heat efficiency will be 2 times higher.

The heat is indirect. So the raw material can not be polluted. It is in conformity with the requirement of GMP. It is easy in washing and maintenance.

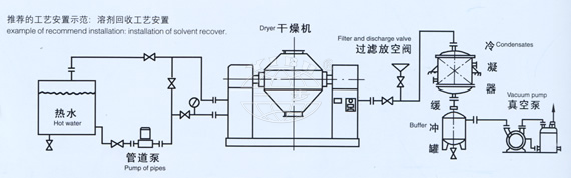

Installation diagram

- Product charging by vacuum transfer system

- Jacket bowl wall design for heating or cooling

- WIP or CIP system

Technical parameters

|

item |

spec |

|||||||||||

|

name |

unit |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4000 |

5000~10000 |

|

total volume |

L |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4000 |

5000~10000 |

|

working volume |

L |

50 |

100 |

175 |

250 |

375 |

500 |

750 |

1000 |

1500 |

2000 |

2500~5000 |

|

heating area |

m 2 |

1.16 |

1.5 |

2 |

2.63 |

3.5 |

4.61 |

5.58 |

7.5 |

10.2 |

12.1 |

14.1 |

|

speed |

rpm |

6 |

5 |

4 |

4 |

4 |

||||||

|

power |

kw |

0.75 |

1.1 |

1.5 |

1.5 |

2 |

3 |

3 |

4 |

5.5 |

7.5 |

7.5 |

|

rotating height |

mm |

1810 |

1910 |

2090 |

2195 |

2500 |

2665 |

2915 |

3055 |

3530 |

3800 |

4180~8200 |

|

total weight |

kg |

825 |

1050 |

1350 |

1650 |

1800 |

2070 |

2250 |

3000 |

4500 |

5350 |

6000~12000 |

|

design pressure inside the tank |

mpa |

-0.09~-0.096 |

||||||||||

|

design pressure of jacket |

mpa |

0.3 |

||||||||||

Remark

1.Speed adjusting motor of 0-6rpm might be chosen according to the user's requirements. The following aspects should be point out when to order:

2.The above-mentioned parameters are calculated based on material density of 0.6g/cm3. If it's over, please point out.

3.If certificate for pressure vessel is required, please point out.

4.If glass lining for interior surface is required, please point out.

5.If the material is explosive, or flammable, the calculation should be made according to trial result.

-

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

-

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

-

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

-

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

-

SZG Series Conical Vacuum Dryer( Rotary Conical Vacuum Dryer)

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow