DG Series Air Stream Dryer For Starch

DG Series Air Stream Dryer For Starch

Product Description

DG series Air stream dryer is the drying plant for to dry maize, potato alike and other starch material processed by wet method after dewatering process. It's also for to dry heat sensitive powder or slice state material with fast speed.

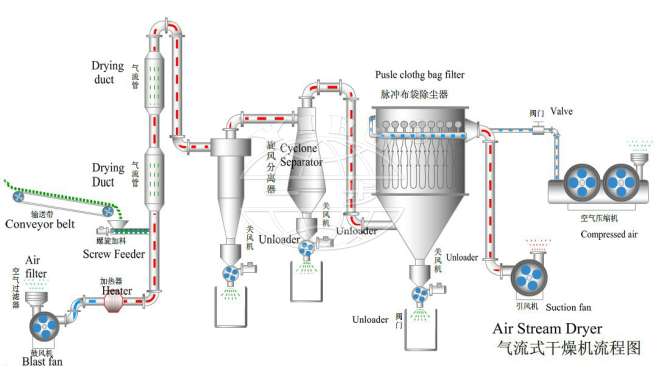

Wet material is dispersed into a stream of heated air (or gas) which conveys it through a drying duct. Using the heat from the air stream, the material dries as it is conveyed.Finished product collected is using cyclones, and/or bag filters. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements.

Principle

1.In the dryer, high-speed hot air stream sustain raw material in the suspending state, then the material is dried. Since air stream speed is very high, and material is suspending in air stream, the heat transfer surface between air and solid is large, heat transfer rate is high, and drying time is short(usually within several seconds). It’s specially suitable for drying heat sensitive materials.

2.In drying process, clean cool air is heated by air heater, and mixed with wet starch sent by spiral feeder and material raiser. Wet starch is dried momentarily. Dry starch is discharged though centrifuge separator and star shape

Feature

1.This machine combines the whirl technology with the fluidity, ejection and smashing step technologies.

2.The equipment is compact and small in size, high in production efficiency and continuous in the production. It has realized that small equipment can perform the large production.

3.The drying capacity for this machine is big but its energy consumption is low. Its heat efficiency is high.

4.The material stay time is very short. The quality of the final products is very good. The machine can be used for drying the heat sensitive materials.

5.For the negative pressure or the micro-negative pressure operation, the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution.

6.High drying efficiency providing low energy costs

7.Continuous processing with short processing time

8.Low operator overheads and minimum maintenance costs

9.Controlled residence time enabling high temperature drying

Flow chart

Product parameters

|

spec |

capacity of starch t/h |

total power KW |

steam consumption Kg/Kg water |

finished starch moisture |

|

DG-0.5 |

0.5 |

|

1.8-2.0 |

12-14% |

|

DG-0.8 |

0.8 |

21.6 |

1.8-2.0 |

12-14% |

|

DG-1 |

1 |

24.6 |

1.8-2.0 |

12-14% |

|

DG-1.2 |

1.2 |

26.6 |

1.8-2.0 |

12-14% |

|

DG-1.6 |

1.6 |

30.1 |

1.8-2.0 |

12-14% |

|

DG-2 |

2 |

47.6 |

1.8-2.0 |

12-14% |

|

DG-2.6 |

2.6 |

59.5 |

1.8-2.0 |

12-14% |

|

DG-3.2 |

3.2 |

75 |

1.8-2.0 |

12-14% |

|

DG-3.6 |

3.6 |

95 |

1.8-2.0 |

12-14% |

|

DG-5 |

5 |

123.4 |

1.8-2.0 |

12-14% |

|

DG-6 |

6 |

170 |

1.8-2.0 |

12-14% |

|

DG-10 |

10 |

223.5 |

1.8-2.0 |

12-14% |

|

DG-20 |

20 |

440 |

1.8-2.0 |

12-14% |

-

DG Series Air Stream Dryer for starch

-

DG Series Air Stream Dryer for starch

-

DG Series Air Stream Dryer for starch

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow