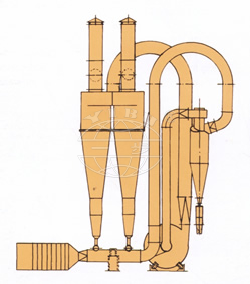

FG Series Positive and Negative Two Grades Air Stream Drying Machine

FG Series Positive and Negative Two Grades Air Stream Drying Machine

Work Principle

The working principle is as follows:the drying of raw material is divided into two steps.First,raw material is dried with the mixing air of the tail air from the second dry and compensating hot air under positive pressure.The dried tail air is discharged to atmosphere.Second,the dried semi-finished product is carried to the second drying with fresh hot air under negative pressure.The finished product is measured and packaged.The used high temperature and low moisture tail air is used for the first grade drying.In this way the good circulating process is completed.The supplementary hot air may be adjusted freely.Therefore the machine has a wide application.

Features

1.The main components in an YIBU Air stream dryer plant are a feed system, the patented drying chamber and a bag filter. Widely acclaimed by customers in a variety of industries all over the world, this patented process provides a faster and more energy-efficient alternative to spray drying. With more than 150 YIBU Air stream installations world-wide YIBU DRYING combines experience and cutting-edge technology into added-value solutions for our customers. Elevated drying temperatures can be used with many products since the flashing off of surface moisture instantly cools the drying gas without appreciably increasing the product temperature which may damage its quality.

2. Wet material is dispersed into a stream of heated air (or gas) which conveys it through a drying duct. Using the heat from the airstream, the material dries as it is conveyed. Product is separated using cyclones, and/or bag filters. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements.

3. The feed system consists of a feed vat where a discontinuous flow of product is buffered and fragmented by an agitator prior to continuous drying. A variable speed feed screw (or pump in the case of fluid feed) forwards the product to the drying chamber.

4. The rotor at the conical base of the drying chamber fluidizes product particles in a drying-efficient hot air flow pattern in which any wet lumps are rapidly disintegrated. Hot air is supplied by a temperature-controlled air heater and speed-controlled fan, entering the drying chamber at a tangent in order to establish a turbulent, whirling air flow.

5. Airborne, fine particles pass through a classifier at the top of the drying chamber, while larger particles remain in the air flow for further drying and powdering.

6. The drying chamber is rigidly designed to withstand pressure shock in the event of explosive combustion of flammable particles. All bearings are effectively protected against dust and heat.

The equipment is widely used for drying granules and powder raw materials from foodstuff,chemical,pharmaceutical and construction materials industries.The products used this kind of equipment for drying are as follows;starch,glucose,fish powder,sugar,edible sugar,lees,feed,plastic resin,coal powder,dyestuff and so on.

Flow chart

Technical parameters

|

spec |

moisture to be |

power kw |

occupied area m2 |

heat efficiency(%) |

|

FG0.25 |

113 |

11 |

3.5x2.5 |

>60 |

|

FG0.5 |

225 |

18.5 |

7x5 |

>60 |

|

FG0.9 |

450 |

30 |

7x6.5 |

>60 |

|

FG1.5 |

675 |

50 |

8x7 |

>60 |

|

FG2.0 |

900 |

75 |

11x7 |

>60 |

|

FG2.5 |

1125 |

90 |

12x8 |

>60 |

|

FG3.0 |

1150 |

110 |

14x10 |

>60 |

|

FG3.5 |

1491 |

110 |

14x10 |

>60 |

-

FG Series Positive and Negative Two Grades Air Stream Drying Machine

-

FG Series Positive and Negative Two Grades Air Stream Drying Machine

-

FG Series Positive and Negative Two Grades Air Stream Drying Machine

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow