QG Series Air stream Dryer( Air Stream Ring Dryer)

QG Series Air stream Dryer( Air Stream Ring Dryer)

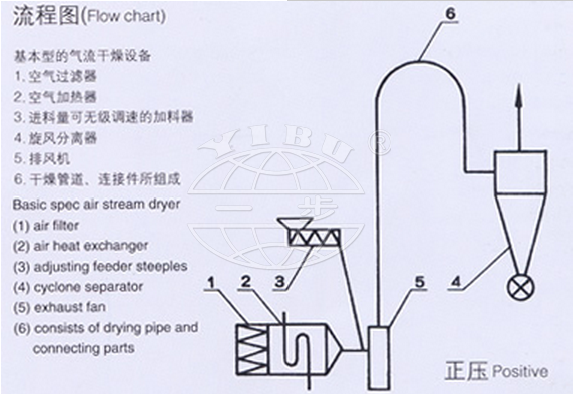

Working Principle

It is equipped with fan that has the function of dispersing.So it is suitable for heat sensitive raw material specially The impeller of fan with high speed can crush the wet and bloked raw material till dispersing During the period of dispersing,it is srirred and mixed. Then the raw material and air are flowing in parallel. It's applicable for drying raw materials that are blocked cake but only surface moisture less than 40%. If the amount to be treated is large or the moisture required of finished products is less than 60%,two grades drying can be used .If the moisture of waw materials is between 40%and 60%,the feeder is difficulty.It is necessary to adapt mixer. Through the method of mixing dry raw material into it to decrease the moisture of raw material. At this time, the total output of dryer will be decrease greatly. It is not suitable in economy. Therefore customer should remove the moisture using machinery method (centrifugal or press) so as to decrease its moisture as possible in order to guarantee the drying operation can be carried our freely .

The equipment can meet different need of raw materials.Besides the mentioned raw materials in basic model,there are hymenal,A.B.C intermediate,ABS resin,white carbon black,tea,catalyst of oxailc acid,promote agent m.d.m,catalyst,deposited carbon powder,N-acetyl-sulfanily chloride,p-aminosalicylic acid, p-phthalic acid,diethyl aniline,titanium dioxide,active carbon,sodium fluosilicate,ammonium sulphate,powder of silicon glue, synthesis resin,calcium sulphate, PP resin, aureomycin, sodium polaysilicate, oral glucose, sodium sulphate, mine of sulphate,mine of phosphorus,BB blue,melting phosphorus fertilizer,tetracycline,ferric oxide,calcium carbonate,titanium/ferric mine,copper mine,powder of white potato,tail coal,stearate,zein,medicine,medical agent,ferric oxide,lees residue and so on.

1.powerful dryer,little investment and the high efficiency of evaporating capacity .

2.Short dryer time.The finished product is seperated from outside,and no pollution with high quality.

3. Heat sourse can be choose from steam,coal fuel,oil fuel and gas fuel hot air furnace.

Equipment Parameter

|

spec |

moisture to be |

Power (kw) |

Occupied |

Height (m) |

|

QG50 |

50 |

7 |

20 |

14 |

|

QG100 |

100 |

13 |

32 |

14 |

|

QG200* |

200 |

21 |

40 |

15 |

|

QG250 |

250 |

24 |

64 |

15 |

|

QG500 |

500 |

43 |

96 |

18 |

|

QG1000* |

1000 |

100 |

120 |

18 |

|

QG1500* |

1500 |

150 |

200 |

20 |

Material Example

|

Material |

Feed moisture content (%) |

Product moisture content (%) |

Hot air inlet temperature /℃ |

Exhaust gas temperature /℃ |

Product particle size /mesh |

|

Aspirin |

2.5-5 |

0.2 |

80 |

60 |

|

|

Rose essence |

35 |

3-4 |

180 |

60 |

40 |

|

Oxalic acid |

4-5 |

0.5 |

120 |

40 |

20 |

|

Sodium acetate |

10 |

2-3 |

80-90 |

|

|

|

MSG |

4-5 |

0.1 |

100 |

|

|

|

Medicinal baking soda |

3 |

0.05 |

110 |

|

|

|

Sodium sulfite |

5-6 |

0.05 |

100 |

40 |

|

|

Glucose |

16-17 |

9.1 |

90 |

40 |

20 |

|

Wheat starch |

40-41 |

12-14 |

240-260 |

50-55 |

|

|

Tight sand |

4-5 |

0.5 |

70-90 |

50 |

|

|

Corn starch |

40 |

13 |

120-130 |

40 |

80-100 |

|

NH |

6 |

0.5 below |

140-150 |

50 |

|

|

Stearic acid salt |

40-50 |

|

105-200 |

70-80 |

200 |

|

Sodium silicate |

12 |

1 below |

400 |

160 |

|

|

Benzoic acid |

25 |

0.5 |

110 |

60 |

80 |

|

Sulfonated coal |

60-70 |

20-40 |

250(inlet) |

|

|

|

Ammonium sulfate |

1.8-2.5 |

0.02-0.08 |

100-115 |

70-90 |

|

|

Sulfoammonium(SN) |

20 |

1 |

110-120 |

50 |

1.5 |

|

Nitrogen based phenol |

10 |

0.4 |

240 |

70 |

|

|

Starch |

42.9 |

12.7 |

147.6 |

38.2 |

0.05 |

|

Activated carbon |

205 |

4 |

455 |

|

|

|

Fused phosphate fertilizer |

5 |

0.3 |

200 |

|

|

|

Tea |

115 |

6.4 |

620 |

|

|

|

M.D.M |

20 |

0.5 below |

150 |

50-80 |

100 |

|

Formaldehyde |

20 |

1 |

135 |

65 |

120-150 |

|

Baking soda |

3.9 |

0.2 |

180-240 |

50-70 |

0.005-0.01 |

|

Microsphere catalyst |

25 |

13 |

500-580 |

130-150 |

40-50 |

|

Ion exchange resin |

4-7 |

0.1-0.4 |

120 |

70-80 |

1-200 |

|

Catalyst |

18-25 |

5 |

110-130 |

60 |

18-20 |

|

Sodium bisulfite |

5.8 |

0.2 |

150 |

108 |

|

|

Crushing carbon |

13.6 |

5.3 |

330 |

100 |

|

-

QG Series Air stream Dryer( Air stream Ring Dryer)

-

QG Series Air stream Dryer( Air stream Ring Dryer)

-

QG Series Air stream Dryer( Air stream Ring Dryer)

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow