LPG Series High-Speed Centrifugal Spray Dryer(drier)

LPG Series High-Speed Centrifugal Spray Dryer(drier)

The state industry standards for this equipment is drafted and specified by YIBU.

Descriptions

The Spray drying is the technology most widely used in the liquid technology shaping and in the drying industry.The drying technology is most suitable for producing solid powder or particle products from liquid materials,such as:solution, emulsion, suspension and pumpable paste states,For this reason,when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies

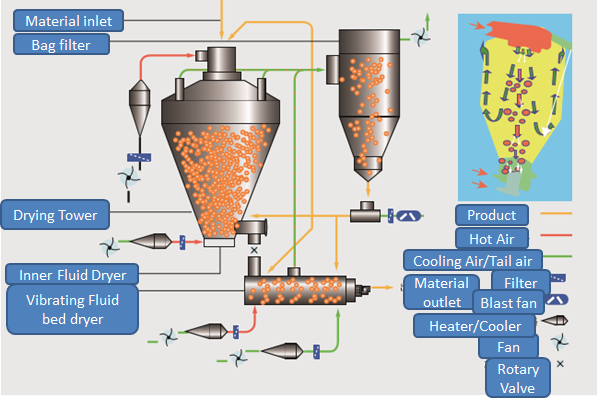

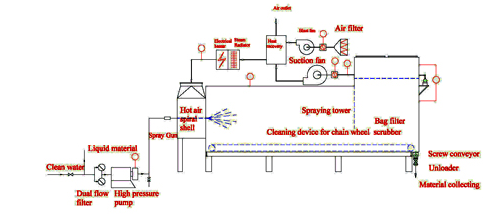

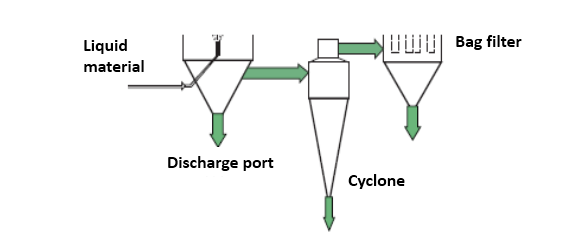

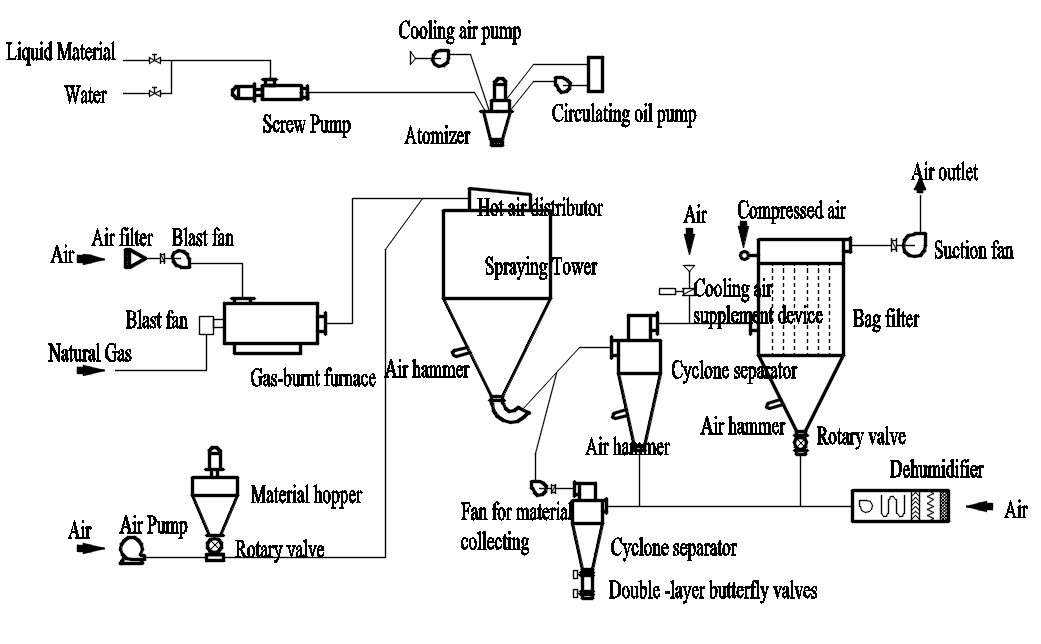

Principle

After been filtered and heated the air enters into the air distrbutor on the top of the dryer.The hot air enters into the drying room in the spiral form and uniformly. Passing through the high-speed centrifugal sprayer on the top of the tower,the material liquid will rotate and be sprayed into the extremely fine mist liquid beads.Trough the very short time of contacting the heat air,the materials can be dried into the final products.The final products will be discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower.

Features

For the LPG series high speed centrifugal spray dryer, it consists of of liquid delivery, air filtering and heating, liquid atomizing, drying chamber, air exhausting and material collecting, control system and so on, the feature for each system as bellow:

1.The liquid delivery system consists of liquid tank, magnetic filter, pump and so on as to ensure the liquid enter into the atomizer smoothly.

2.Air filtering system and heating system

Before the fresh air enter into the heater, it should pass through the Pre&post filter first, and then enter the heater for heating. For the heating method, there are electrical heater steam radiator, gas furnace and so on. Which method to choose depends on the customer site conditions.To ensure the drying medium enter into the drying chamber with high purity, the heated air should go through the High efficiency filter before enters the drying chamber.

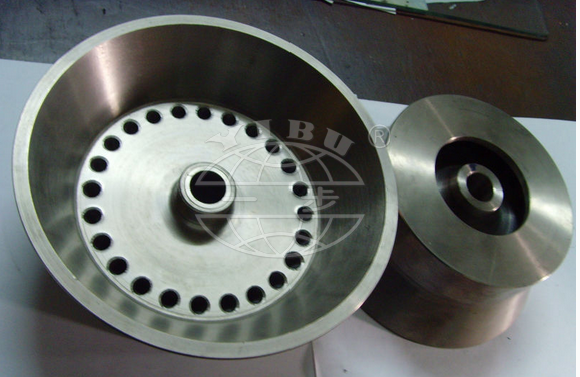

3. Atomizing system

The atomizing system consists of high speed centrifugal atomizer with inverter and so on.

The powder from the high speed centrifugal atomizer is between 40-120 microns.

4. Drying Chamber system

The drying chamber consists of the spiral shell, hot air distributor, main tower and relevant fittings.

The Spiral shell and hot air distributor: the spiral shell and hot air distributor at the air inlet of the tower top can regulate air flow rotation angle according to the specific condition, guide the air flow inside the tower effectively and avoid the material stick on the wall.in the middle there is the position for installing the atomizer.

Drying tower: The inner wall is SUS mirror sheet, ad welded by the arc welding. The insulation is rock wool.

The tower is manhole and view port as to convenient to clean and maintain the tower. For the Tower body cross interface, pipe elbow are arc butt design, reduce dead angle; sealed type.

The main tower is equipped with air hammer, controlled by the pulse, and hitting the main drying tower timely as to avoid the dust stick on the wall

5. Air exhausting and product collecting system

For the material collecting system, there are several types. Such as cyclone, cyclone+bag filter, bag filter, cyclone +water scrubber and so on. The method is depending on the material property itself. For the filtering system for the outlet air, we have filter on request.

6. Control system

HMI+PLC, each parameter can be displayed on the screen. Every parameter can be controlled and recorded easily.

Flow chart

Centrifugal spray atomizer Features

1.The drying speed is high when the material liquid is atomized,the surface area of the material will increase greatly.In the hot-air flow,95%-98% of water can be evaporated at a moment.The time of completing the drying is only several seconds. This is especially suitable for drying the heat sensitive materials.

2.Its final products own the good uniformity, flow ability & solubility. And the final products are high in purity and good in quality.

3.The production procedures are simple and the operation and control are easy.The liquid with moisture contents of 40-60%(for special materials,the contents might be up to 90%).can be dried into the powder or particle products once a time. After the drying process, there is no need for smashing and sorting,so as to reduce the operation procedures in the production and to enhance the product purity.The product particle diameters,looseness and water contents can be adjusted through changing the operation condition within a certain range. It is very convenient to carry out control and managment.

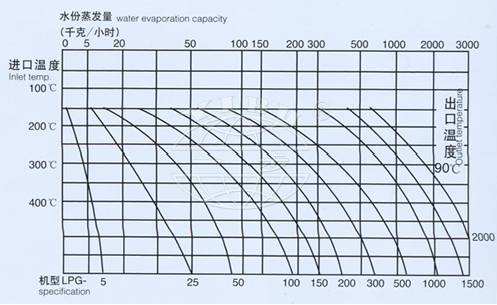

Notes: for water evaporation capacity ,material property ,the inlet and outlet temperatures ,please refer to the following diagram .

Technical parameters

|

m\parameter\spec |

LPG |

|||||

|

5 |

25 |

50 |

100 |

150 |

200-10000 |

|

|

inlet temperature ℃ |

140-350 automatically controlled |

|||||

|

outlet temerature ℃ |

~80-90 |

|||||

|

Max.water evaporation capacity |

5 |

25 |

50 |

100 |

150 |

200-10000 |

|

centrifugal spraying nozzle transmission mode |

compressed air transmission |

Mechanical transmission |

||||

|

Rotation speed rpm |

25000 |

18000 |

18000 |

18000 |

15000 |

8000-15000 |

|

Spraying disc diameter mm |

50 |

100 |

120 |

140 |

150 |

180-~ |

|

Heat supply |

Electricity |

Electricity+steam |

Electricity+steam,fuel oil and gas |

Settled by users themselves |

||

|

Max.Electric heating power kw |

9 |

36 |

63 |

81 |

99 |

|

|

overall dimensions m |

1.8×0.93 |

3×2.7 |

3.7×3.2 |

4.6×4.2 |

5.5×4.5 |

Depends on the concrete conditions |

|

Dried powder restoring tate % |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

|

Note:For the water evaporation capacity, material property,the inlet and outlet tempratures,please refer the following diagram for reference. |

||||||

Applications

Chemical Industry: Sodium fluoride(potassium),alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

Plastics and resin: AB,ABS emulsion,uric acid resin,phenolic aldehyde resin,urea-formaldehyde resin,formaldehyde resin,polythene,poly-chlotoprene and etc.

Food Industry: Fatty milk powder,protein,cocoa milk powder,substitute milk powder,egg white(yolk),food and plant,oats,chicken juice,coffee,instant dissoluble tea,seasoning meat,protein,soybean,peanut protein,hydrolysate and so forth.

Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, sorbic acid potassium and etc.

Ceramic: aluminium oxide,ceramic tile material,magnesium oxide,talcum and so on.

-

LPG-C high-speed centrifugal spray dryer(drier)

-

LPG-C high-speed centrifugal spray dryer(drier)

-

LPG-C high-speed centrifugal spray dryer(drier)

-

LPG-C high-speed centrifugal spray dryer(drier)

-

Detail image

-

Detail image

-

Detail image

-

Detail image

-

Detail image

-

Detail image

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow