ZLG Series Spray Dryer For Chinese Traditional Medicine Extract

ZLG Series Spray Dryer For Chinese Traditional Medicine Extract

The industry standards for This type of spray dryer is drafted and issued by YIBU

State standards

No.:JB/T 20132-2009

Industry

standards No.: GB/T 32237-2015

Description

The machine adopts full sealing for it. All parts are made of stainless steel. It is equipped with three grades of filter. The filtered air is one hundred thousand grades. The cooling device of wall is installed at the cylinder body. It makes the wall temperature less than 80℃。Air sweeping device is installed inside the drying tower. The product will not be burnt or deteriorated even stays on the way. The collection rate of powder is raised greatly. Moreover will not cause medicine mixed or wall stick.

Principle

Basic Principle: high-speed centrifuge atomizing for the extract of traditional Chinese medicine is an application of centrifuge atomizing technique. It is an high-speed atomizing dryer. The following problems are solved.

1. Raw material is stick to the wall and the rate of powder collecting is low.

2. Because the staying time of raw material at wall is long, the phenomenon of burnt and degeneration can be produced.

3. It is difficult to clean and can not meet the requirement of GMP

4.Low in output: Model LPG-150 atomizing centrifuge dryer can process 50-60kg/h of raw material liquid. In view of this, according to the properties and process requirements of the extract of traditional Chinese medicine, our factory researched and designed the special dryer for the extract of traditional Chinese medicine and won items of china patent.It solves the historical difficult problems in drying the extract of traditional Chinese medicine.The color of dried raw material is good.The dried raw material does not degenerate.It raises the economic benefit greatly.

Features

Compared to ordinary LPG high-speed atomizing dryer,it has the following features

(1).Adopted three-grade air filter,the inlet air is one hundred thousand grade.

(2).Adopted wall cooling device,the temperature of inner wall will be on more than 80℃.Even if raw material is stayed on the wall,it will not be burnt

(3).Its whole volume is 3.5 times of standard LPG high-speed atomizing dryer.

(4).Adopted quick washing device,it is can meet the requirements of production for varieties if products.

(5).Adopted wet-dedusting,there is no powder dust out.It is in conformity with the requirements of GMP.

(6).Adopted air sweeping device ,the clean effect is satisified.

(7).Equipped with two sets of atomizer and adopted frequency inverter control.

(8).Adopted PLC control and display,and adapted frequency control.

(9).Equipped with washing device on request.

(10).Adopted the seal transport by dry air on request.

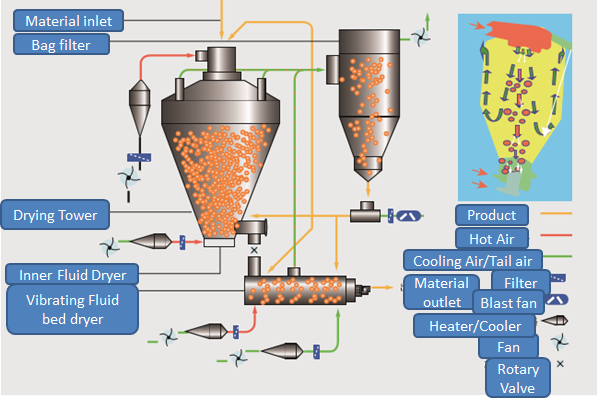

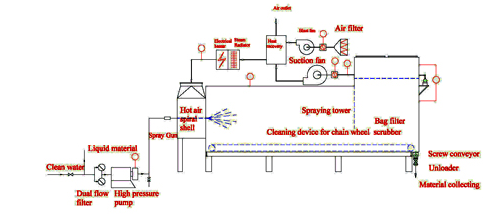

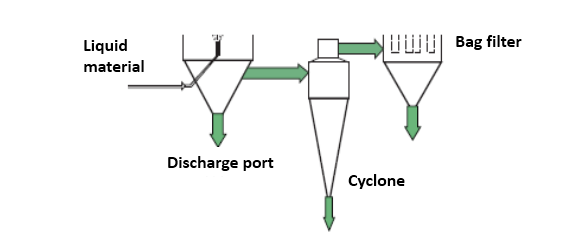

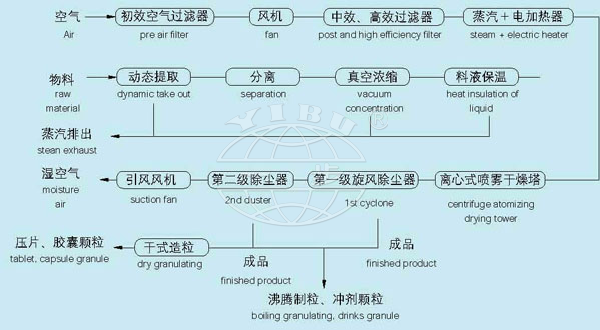

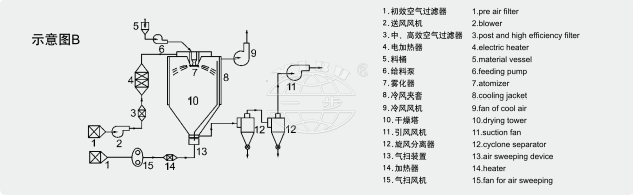

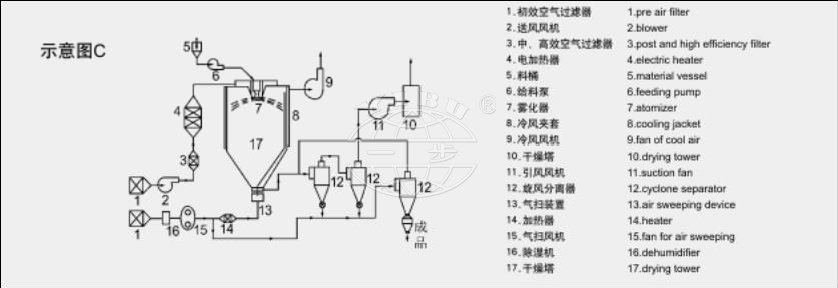

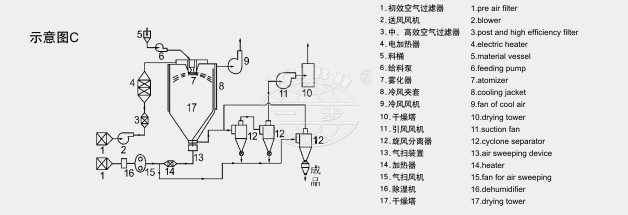

Flow chart

Technical parameters

|

spec |

ZLG-25 |

ZLG-50 |

ZLG-80 |

ZLG-100 |

ZLG-150 |

ZLG-200 |

ZLG-300~1000 |

|

|

evaporation capacity(kg/h) |

25 |

50 |

80 |

100 |

150 |

200 |

300~1000 |

|

|

process amount of material liquid(kg/h) |

25-34 |

50-68 |

80-108 |

100-135 |

150-203 |

200-270 |

300-1100 |

|

|

output of finished product(kg/h) |

4.8-7.2 |

9.2-14 |

14.8-22.4 |

18.4-28 |

28-42 |

36.8-56.4 |

55-980 |

|

|

solid content of material liquid(%) |

18-25 |

|||||||

|

moisture content of finished product(%) |

3-5 |

|||||||

|

electric powder(kw) |

63 |

99 |

132 |

153 |

204 |

246 |

330~ |

|

|

heat source |

steam plus electricity |

|||||||

|

collecting method of product and its efficiency |

two-grade cyclone or one-grade cyclone and one-grade web-method dedusted of 95% |

|||||||

|

automatic control meters and instruments |

indicator of not air and exhaust air temperature |

|||||||

|

temperature of air inlet(℃) |

150-200 |

|||||||

|

temperature of air outlet(℃) |

80-100 |

|||||||

|

overall dimensions(mm) |

L |

7000 |

8000 |

9800 |

11000 |

12200 |

14100 |

15000~based on design |

|

W |

4000 |

5000 |

5700 |

6200 |

7000 |

7800 |

9000~based on design |

|

|

H |

6900 |

7400 |

8000 |

8900 |

10000 |

11000 |

12000~based on design |

|

Attention to order

1.Liquid name and property: solid contents (or water contents), viscosity, surface tension and PH value.

2. Dry powder density residual water contents allowed, particle size, and maximum temperature allowed.

3. Output: shift time daily.

4. Energy that can be supplied: steam pressure, electricity properly, fuel of coal, oil and natural gas.

5. Control requirement: whether or not the inlet and outlet temperatures should be controlled. Powder collection requirement: whether it's necessary to use cloth bag filter and the requirement of the environment of the exhausted gas.

6. Other special requirements.

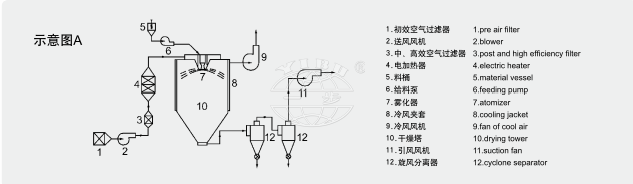

Schematic of installation

-

ZLG Series Spray Dryer For Chinese Traditional Medicine Extract

-

ZLG Series Spray Dryer For Chinese Traditional Medicine Extract

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow