Continuous production of lime juice by vacuum freeze drying

Source: | Date:

2010-08-31

| Hits:

Keywords:

Lime (Citrus aurantifolia) is an important agricultural product in Thailand. Lime has been used to prevent scurvy, a disease caused by a deficiency of vitamin C. Traditionally, lime has been used as a remedy for indigestion, heartburn and nausea. It also has cooling effects on fevers and can help ease coughs and various respiratory disorders (3), (7). The preservation or modification techniques of lime during seasoning are necessary in order to preserve lime for off season, apply for other purposes and also to control the price of lime. In this study, the vacuum freeze dryer technique is designed to produce lime juice powder in order to preserve lime products.

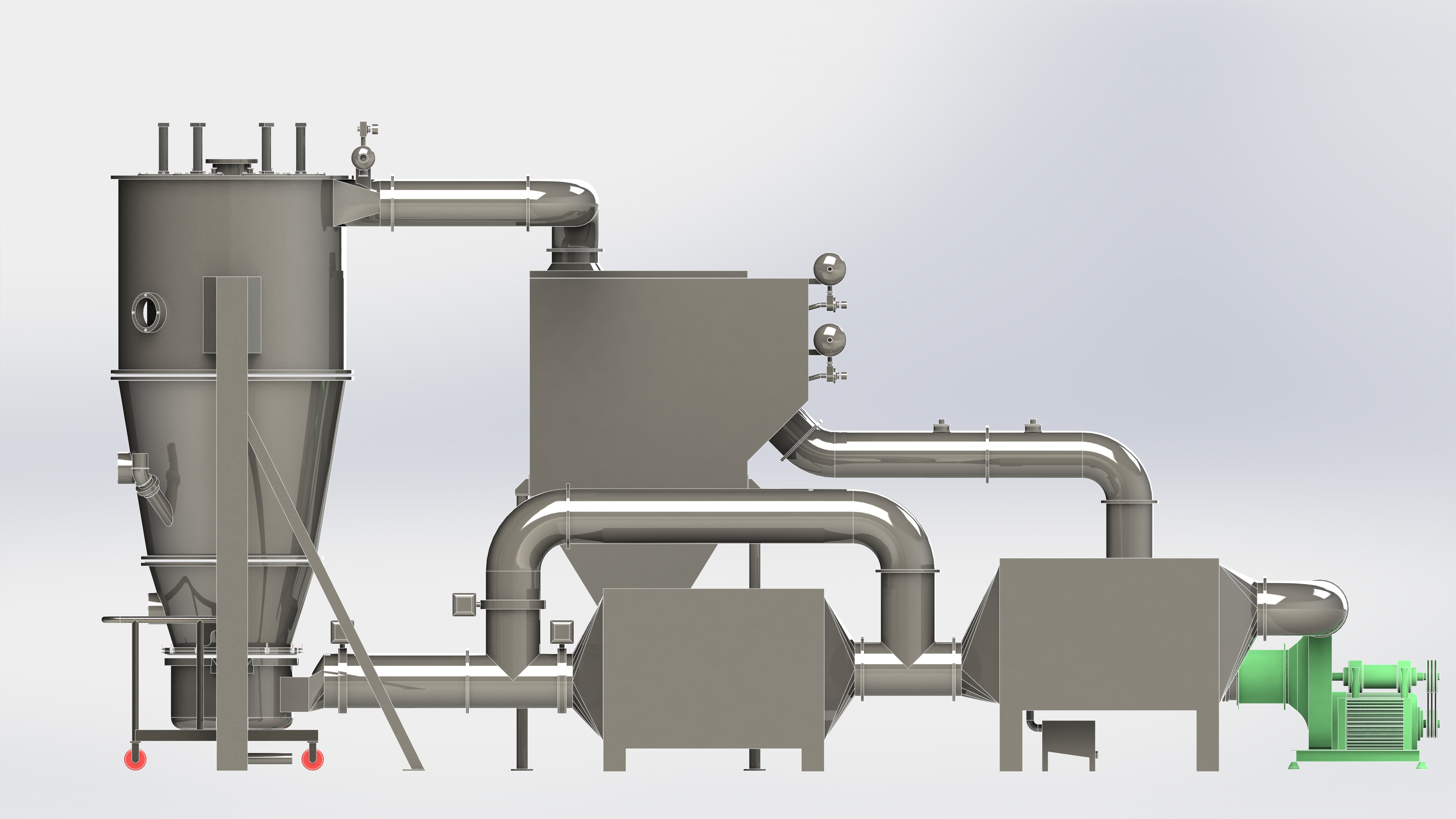

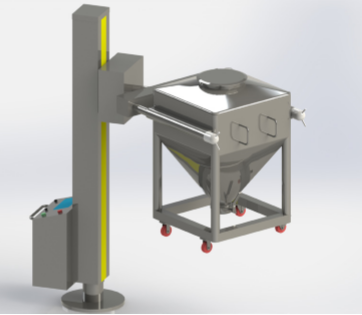

Vacuum freeze-drying is one of the best methods for food drying equipment and producing final products of highest quality as comparing to other drying technologies. Besides, as the moisture content of products is reduced, the process temperature is decreased and most of the deterioration and microbiological reactions are also ended. Therefore, both preservation and value-add of high-value food are achieved by using this technology (9), (10). The vacuum freeze-drying consists of two important systems; freezing system and freeze drying system. Freezing required the removal of heat. Ideally, two-component liquid systems, water and solute, are crystallized (6). In order to have freezing operations to be cost-effective, it is necessary to optimally design the efficient refrigeration system. Such a system includes compressor, condenser, evaporator and axial fan (1), (2), (4), (6), (8). The other part of the system, the freeze drying must remove water of product by sublimation process and also involves mass and heat transfer (8). Thus, the refrigeration system must work for both processes appropriately.

Vacuum freeze-drying is one of the best methods for food drying equipment and producing final products of highest quality as comparing to other drying technologies. Besides, as the moisture content of products is reduced, the process temperature is decreased and most of the deterioration and microbiological reactions are also ended. Therefore, both preservation and value-add of high-value food are achieved by using this technology (9), (10). The vacuum freeze-drying consists of two important systems; freezing system and freeze drying system. Freezing required the removal of heat. Ideally, two-component liquid systems, water and solute, are crystallized (6). In order to have freezing operations to be cost-effective, it is necessary to optimally design the efficient refrigeration system. Such a system includes compressor, condenser, evaporator and axial fan (1), (2), (4), (6), (8). The other part of the system, the freeze drying must remove water of product by sublimation process and also involves mass and heat transfer (8). Thus, the refrigeration system must work for both processes appropriately.

Pre: IPEX2010

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products