Advanced Granulation Technology(3)

Methods and Materials

Manufacture of AGT CD-CHO

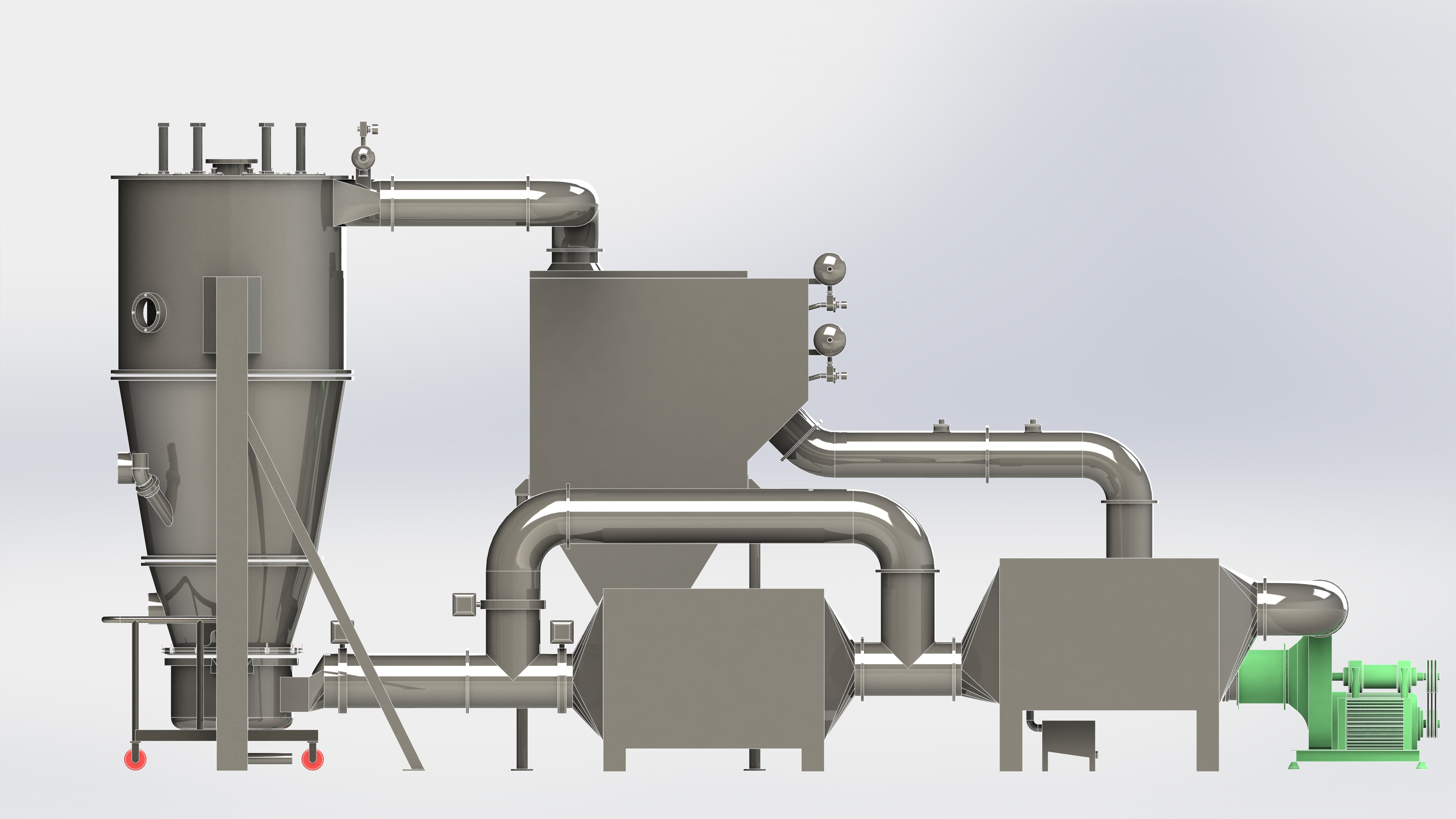

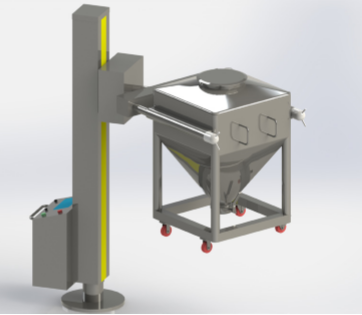

AGT CD-CHO medium was produced by a top spray fluid bed granulation process. All component ingredients were initially processed by hammermilling to establish a uniform particle size. The attritted biochemicals were then transferred to a fluid bed processor that suspended the powder on a column of conditioned air. The levitated powder was sprayed with a fine mist of aqueous solution. Under these controlled conditions, the moistened media particles fuse together with simultaneous water evaporation, producing a porous agglomerate or granule that gives AGT its unique properties. We used fluid bed granulating equipment of three different working capacities: 22L for the 9kg scale, 220L for the 90kg scale and 1100L for the 500kg scale. The finished AGT CD-CHO medium was reconstituted with distilled/deionized water, stirred for 10-15 minutes, and sterile filtered without further supplementation or pH adjustment.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow