Urea Granulation Technology of Double Drums with a Fluidized Bed(3)

1. The Major Contents of DDG Technology

*a) Technology Name:

Urea Granulation Technology of Double Drums with a Fluidized Bed

*b) Technology Brand:

DDG

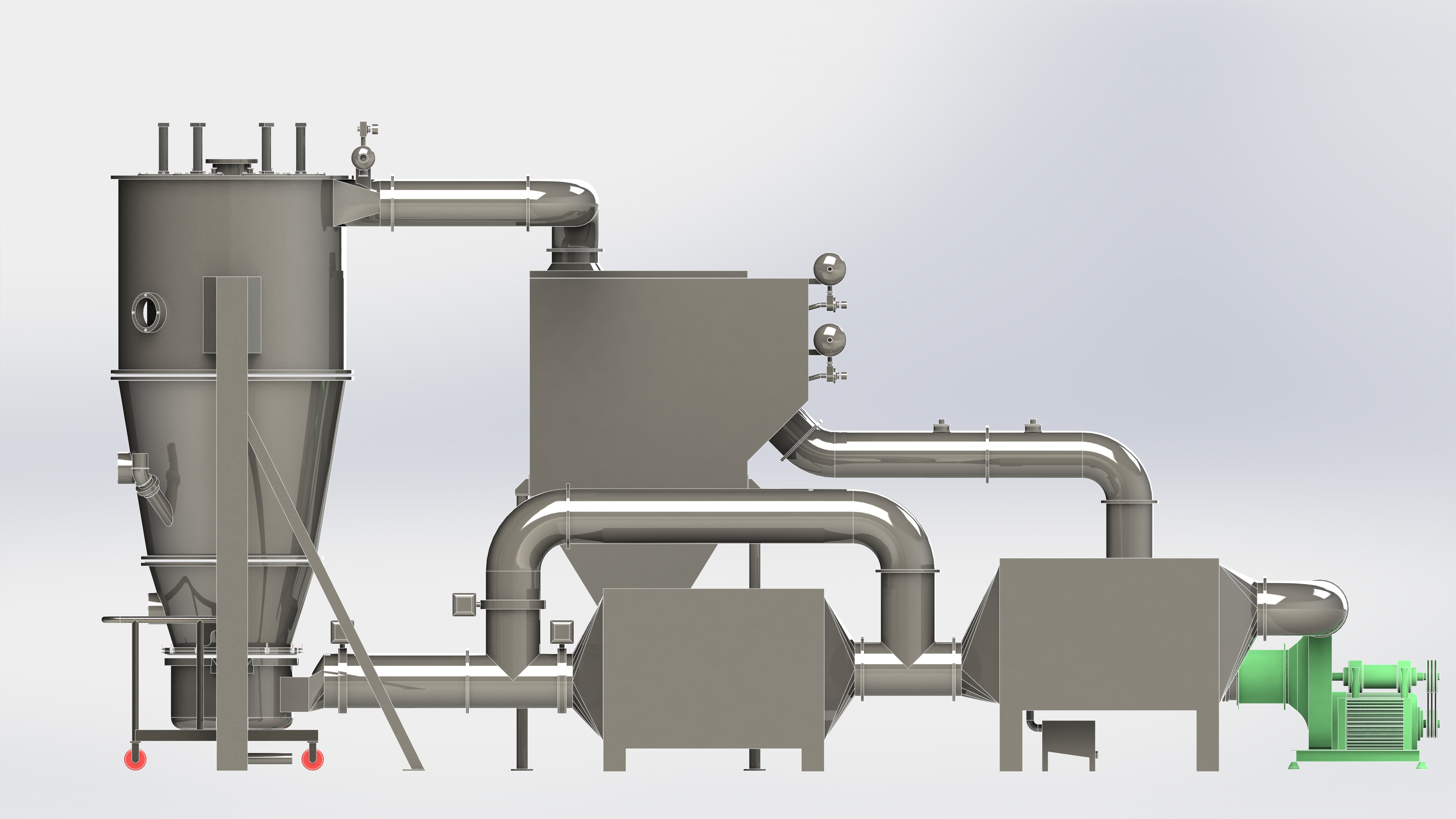

*c) A Brief Introduction to the DDG Technology

The basic contents of the DDG Technology is to put the melted urea into

the granulation drum, and make it to meet the prilled urea back from the

shaken sieve, so that to make the pellets enlarged until to reach the

required size. After the sieved pellets come out of the granulation drum, let

the eligible granular urea move into the cooling drum for cooling down,

then the product can go out for sale. The tail gas will be out to the sky after

being washed up by the washing system.

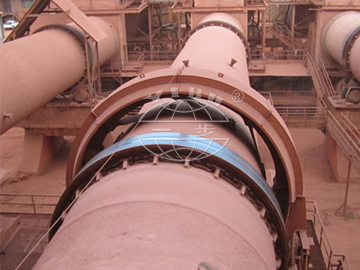

*e) The Patent Equipments:

The key facilities of DDG technology are consisted of the following two

rotary drums:

*(1) The Granulation Drum with a Fluidized Bed:

In the granulation drum, a fluidized bed and a sprayer and other

components are installed properly. In the drum, the prilled urea in

waterfall shape will meet the atomized melting urea from the sprayer,

and will be enlarged into granular ones until it reaches the required

size, and then go out of the drum. The special design makes the

fluidized air pressure much lower than that of the same technology

applied today in the West. The design of mechanical atomization

sprayer leaves out the air atomization. These two points are the

technical bases for energy saving in production.

*(2) Water Cooling Drum:

There is a water cooler installed in the drum. The special design

makes the patent equipments use water cooling instead of wind

cooling. Therefore, it has simplified the treatment process of the cool

wind polluted by the urea powder. This is the technical base of

energy saving in the cooling system.

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow