New trend-Process For Producing Free-Flowing Granules With Superheated Stream(13)

By contrast , the teaching according to the invention builds on the surprising observation that useful materials and mixture thereof from the field of wetting agents ,detergents and /or cleaning products and ,more particularl, correponding mixtures containing surface-active components lead to totally different results on the one hand where drying is carried out in superheated steam and , on the other hand ,where drying is carried out in conventional hot gases .In the second case ,a temperature and moisture gradient is rapidly established in the drop inwards from its surface .The surface of the drop dries rapidly and a solid crust is formed Liquid diffuses outwards from the inside of the drop ,substances dissolved in th water crystalling out when their solubility is exceed .This result in further hardening and thickening of the outer shell .Bysontrast ,the drying of a drop in superheated steam follows a totyally different course.When the drop not yet heated to boiling temperature comes into cntact with superheated steam,water initially condenses o nteh surface ,a film of water being formed around the drop ,The heat of condensation is transferred to the interior of the drop .When the evaporation temperature is reach in the drop ,drying in the one-component water/steam system takes place throughout the drop in accordance with the vapor pressure curve ,i.e. the water begins to evaporate throughout the drop .In other wors, a rigid outer shell .which would prevernt the drop from contracting any further ,is not formed right at the beginning ,as in drying with hot gases.the drop dries uniformly over its cross-section numerous small steam channels evidently deing established throughout the solid structure formed.The dry mass formed thus becomes extremely porous .The teaching according to the invention makes use of this. This high porosity of the solid material can be the basis for substantially improved solubility in wter and /or for a greatly increased absorption capacit of the steam-dried material for liquid phases by comparison with concentionally dried material.According to the invention ,therefore ,not only does the outer particle surface of the granular carrier beads becomes accessible to coation with the coatinf composition ,the inner surface and hence ultimately the entire freely accessible inner space of the carrier beads dried in the superheated steam canbe coated or filled with the coating composition

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

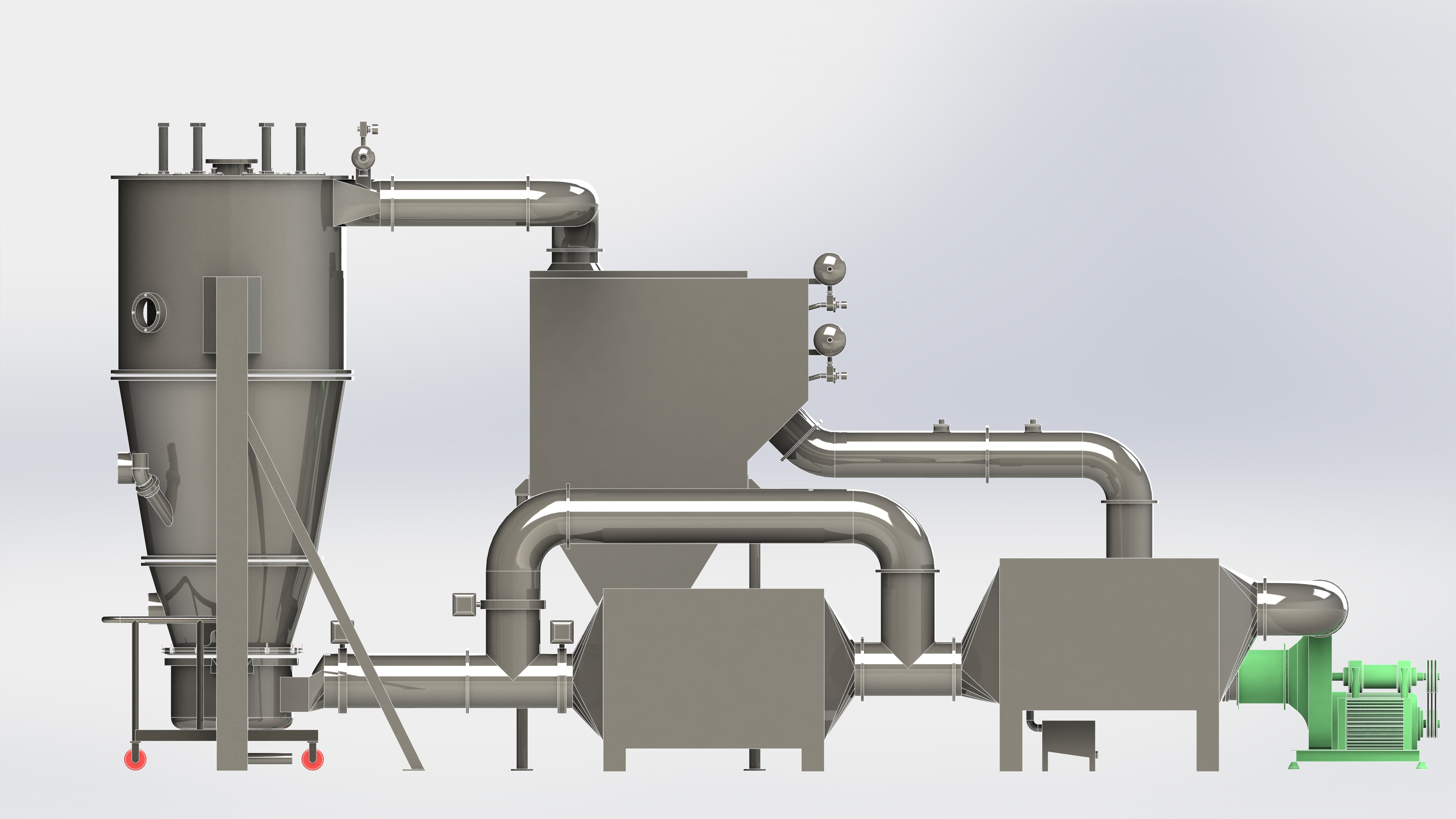

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow