Push your Spray Dryer to the Limit.

Source: | Date:

2014-07-20

| Hits:

Keywords:

Introduction

The key to producing commodity dairy powders and other products in spray dryers is to maximise the production through the dryer, while ensuring that stoppages due to blockages in the duct work and cyclones are minimised. (Figure 1 shows a cyclone that is blocked by a dairy powder sticking to the walls of the cyclone.)

Figure 1

Work completed at Massey University over the last few years1,2,3,4,5 has demonstrated that there is a characteristic temperature above the glass transition temperature of the dairy powder at which a powder becomes instantaneously sticky. (An outline of this work is shown in a complimentary poster at this conference5). Since the surface of the particle is what determines whether a particle becomes sticky or not, what is needed to determine whether a particle will be sticky as it leaves the drier are the outlet air temperature and relative humidity of the air in contact with the powder particles.

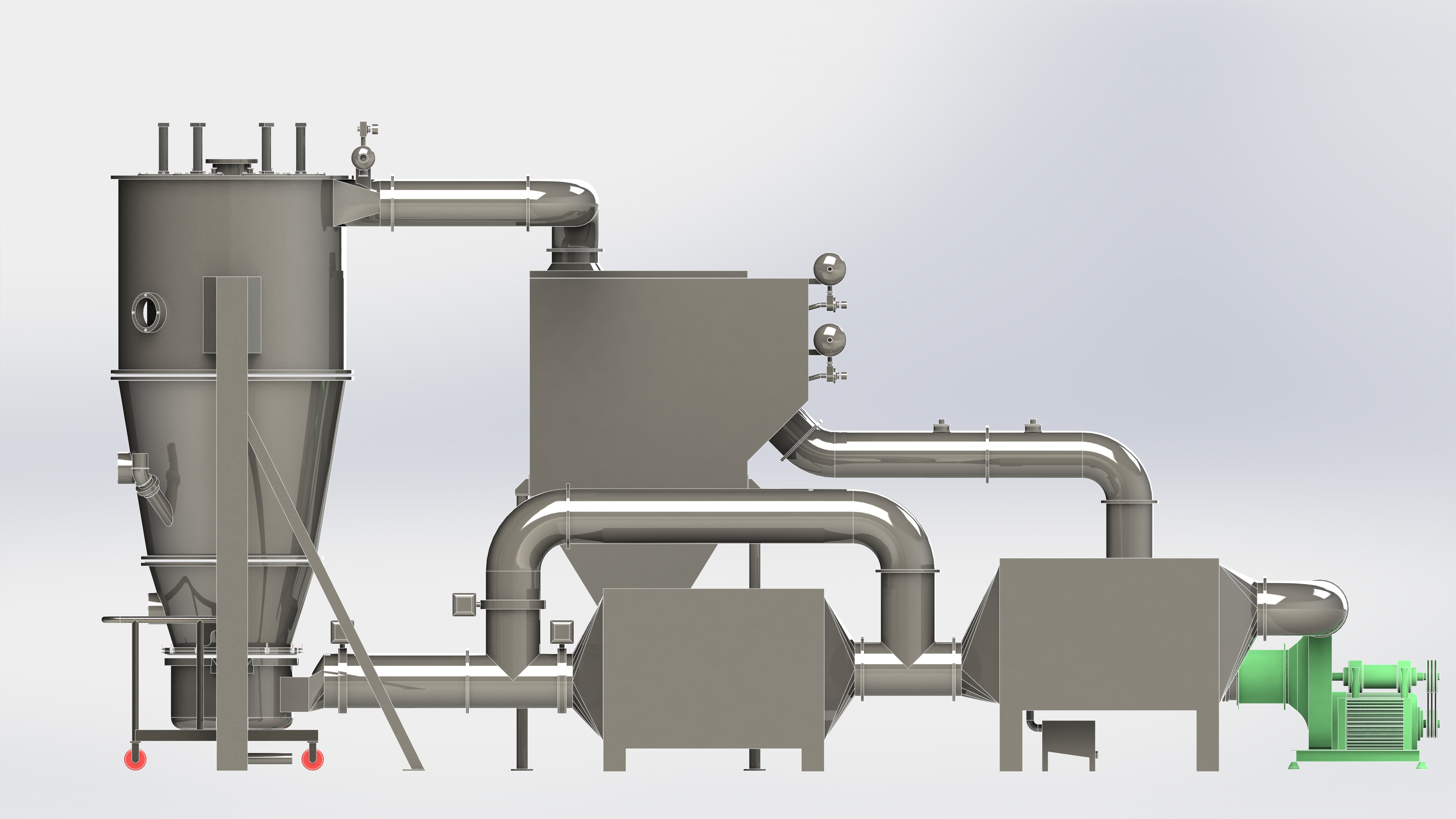

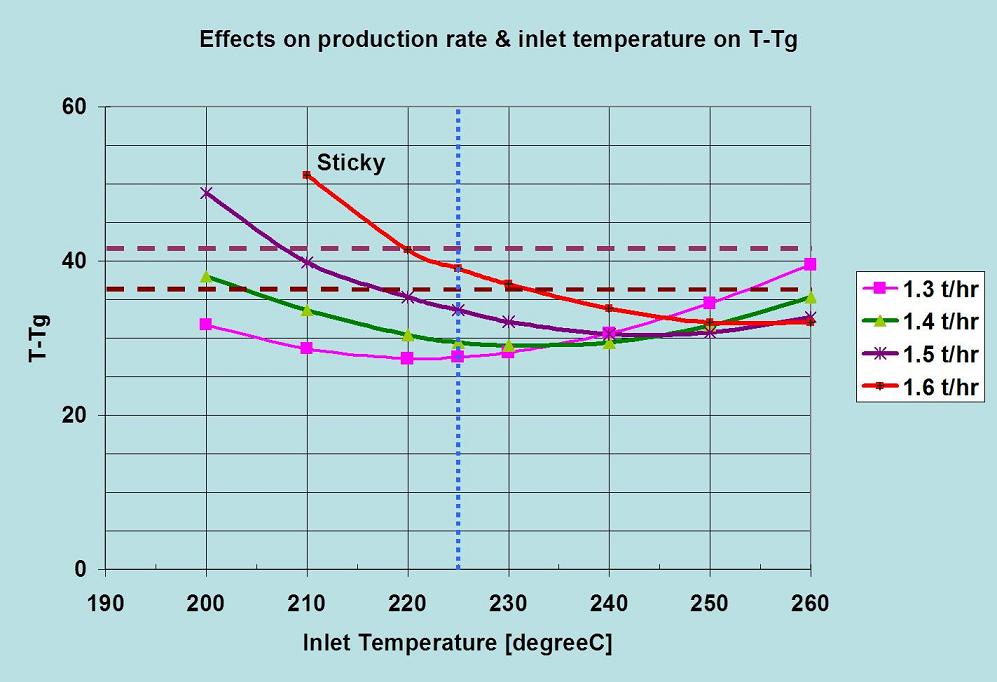

Figure 2 Figure 3

Results and Discussion

A spreadsheet was constructed which takes the production rate, the solids concentration of the feed, the inlet air flow rate, temperature and relative humidity before heating and the temperature after heating and it uses this information by way of a total heat and mass balances to calculate the outlet air conditions. Assumptions are made about the amount of heat lost from the drier and this assumption can be adjusted to enable a particular driers performance to be matched when running on water during startup. These startup conditions can also be used to determine the air flow rate, if there is no independent measurement of the air flow through the drier.

The mass and energy balance can easily be altered to account for additional extras such as an internal fluidised bed operating at the bottom of the drier.

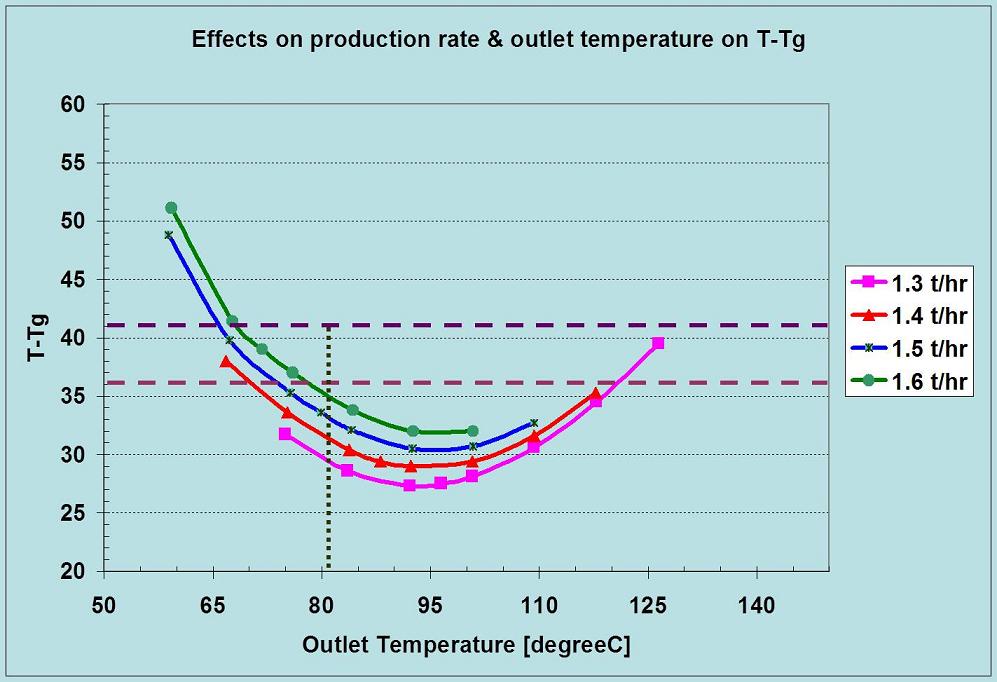

Once the exit air temperature is known, the surface conditions of the powder particles can be determined from assuming that the surface is in equilibrium with the air. Work completed at Massey University, has shown that this is a reasonable assumption. This enables the glass transition temperature for the sugars present to be estimated and hence it is possible to plot how the T-Tg of the powder surface changes for different operating conditions for the spray drier. Figure 2 shows a plot T-Tg of a powder surface as a function of the Outlet air temperature of the drier and production rate are varied. The dotted lines show the expected range in which this particular powder becomes instantaneously sticky and hence is the area that should be avoided.

To use this graph, one would locate the current operating point of the drier; say, for example it had a production rate of 1.4 tonnes per hour at an outlet air temperature of 81°C then looking at the figure one can see that the production rate could safely be increased to 1.6 tonnes per hour while maintaining the outlet air temperature at 81 °C. This would mean that the inlet air temperature would have to be increased to maintain the same outlet air temperature with the increased production.

The figure implies that even higher production rates are possible if the outlet air temperature is allowed to rise to around 95°C.

Figure 3 shows a plot of T-Tg of a powder surface as a function of Inlet air temperature and production rate. This shows an inlet air condition of 225°C and a production rate of 1.4 tonnes per hour is not optimum. Either the production rate could be safely increased to 1.5 tonnes per hour, while keeping the same inlet air temperature, or if the production rate is kept at 1.4 t/h then the inlet air temperature could be safely reduced to 207°C, thus saving energy.

Conclusion

Dairy powders have a characteristic temperature, X°C, above the glass transition temperature of the sugars in the powder (usually just lactose), at which they start to deposit on the dryer and duct walls. Once known, spray dryer throughput can be optimised by altering the throughput and/or inlet air temperature to ensure the existing powder is kept just below this critical point.

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products