LZL Series Fluidized-vibrating And Continuous granulator

LZL Series Fluidized-vibrating And Continuous granulator

Discription

LZL series Fluidized-vibrating and continuous granulator is the newly- designed continuous granulator researched and developed by YIBU .Its features as bellow: small volume ,high efficiency , energy save ,the granule from it with high quality and so on .

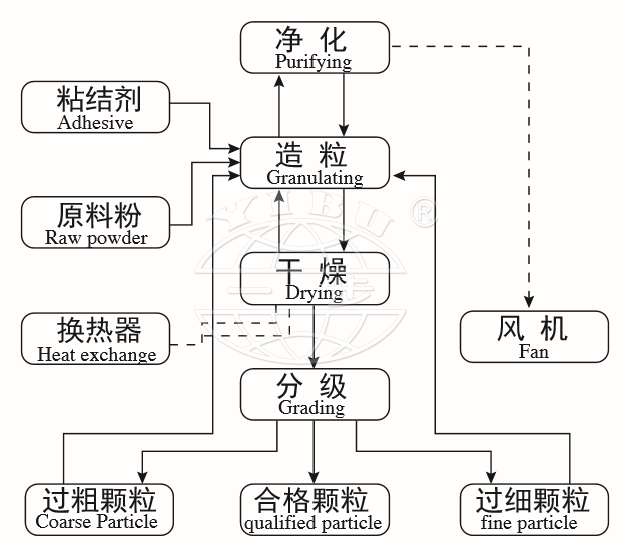

The powder is fed into the granulating chamber by the material feeder system . By the effect of hot air , the powder is in the fluid state inside the granulating chamber . When the powder in the granulating chamber reaches a certain concentration, the atomizing system begins to spray the rationing liquid . When the powder contact with the liquid ,the powder will has the surface tension,and begin to agglomerate powder .with the size of granule become bigger and bigger , the granule will Overcome the terminal operating speed into the drying chamber through a hollow throat when the size of granule reached the certain requirement . By the hot air flow and vibrating , the granule will be dried and move towards ,after some time , the granule will reach discharge port . The Qualified granule will be discharged out after grading , and for the unqualified granule will return to the granulating chamber for further granulation.

Main Characteristics :

● material feeding→granulating→Drying →grading →finished product discharge,the whole process run continuously.

●The whole process is carried out in a closed state, no flying dust as to avoid the material loss and material site pollution.

● The size of the finished granule is uniform, stable ingredients and full dry ;

●The heating time for the material is short ,so there is no thermal reaction occur.

High production efficiency, less consumption of energy, greatly reduce production costs

●Disassembling and installation is very sample , it is very convenient for maintenance and clearance.

●Less area occupied, it can greatly reduce the investment on the infrastructure;

●The production capacity is big , it can achieve the capacity of 1t/h.

In summary, the fluidized-vibrating and continuous granulator has the absolute advantages , no matter in the process, the efficiency, the energy consumption and the investment , it can bring great economic benefits for the user.

Features

The biggest characteristic of the machine is that only using this machine can complete the production process of granulation, drying, particle grading in one step. Meanwhile, the whole process is continuously carried out in a closed state, no flying dust as to avoid the material loss and air pollution to meet the requirement of the GMP .

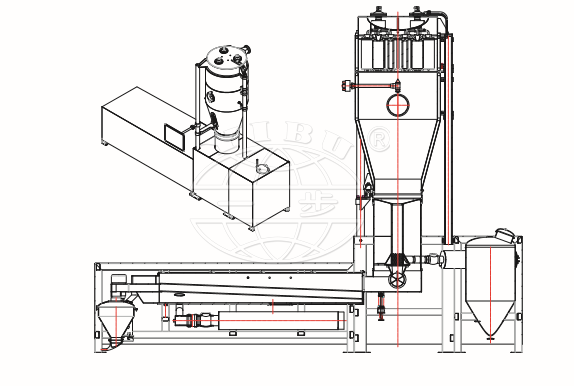

Overall Drawing

Applications

Pharmaceutic industry : the granulating for tablet ,granule ,capsule and so on.

Foodstuff industry : the granulating for all kinds of instant solid drink.

Chemical industry : the granulating for Various pigments, dyes and raw materials

Ceramic industry: the granulating before all kinds of tiles forming;

The granulating for other industry.

The granule data for Several typical material

|

Name |

Adzuki beans powder |

Soybean |

Starch |

Gastric |

VC |

Yanke |

White |

|

Size of raw |

<100 |

80~150 |

<200 |

<150 |

<120 |

<100 |

<200 |

|

Initial moisture(%) |

4 |

5 |

3 |

4 |

1.5 |

5 |

5 |

|

Temperature |

55 |

60 |

60 |

60 |

55 |

55 |

60 |

|

Granulating |

5 |

6 |

5 |

7 |

7 |

15 |

7 |

|

Drying time |

14 |

15 |

15 |

15 |

15 |

18 |

15 |

|

Particle range |

10~40 |

15~40 |

15~60 |

15~40 |

15~40 |

14~26 |

10~40 |

|

Granule |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

The moisture |

3 |

4 |

5 |

5 |

1.5 |

5 |

4 |

|

Particle tensity |

2.5 |

2.6 |

3 |

2.8 |

2.7 |

3.5 |

2.7 |

Main technical parameter

|

model LZL- |

15 |

30 |

50 |

100 |

200 |

300 |

500 |

1000 |

|

|

Capacity (kg/h) |

10~20 |

25~35 |

40~60 |

90~110 |

180~220 |

270~330 |

450~550 |

900~1100 |

|

|

Particle range(mm) |

0.1~3 |

0.1~3 |

0.1~3 |

0.1~3 |

0.1~3 |

0.1~3 |

0.1~3 |

0.1~3 |

|

|

Fan Power(Kw) |

1.1 |

3.0 |

4.0 |

5.5 |

11 |

18.5 |

22 |

30 |

|

|

heat consumption for drying (kcal./h) |

6062 |

10103 |

16838 |

33676 |

67352 |

101028 |

168380 |

336760 |

|

|

Compressed air |

0.4 |

0.4 |

0.5 |

0.8 |

1.1 |

1.5 |

2.0 |

2.7 |

|

|

the size for the installing the main machine |

A( mm) |

2100 |

2300 |

2400 |

2700 |

2900 |

3300 |

3500 |

3900 |

|

B( mm) |

2900 |

3370 |

3900 |

4100 |

4800 |

5400 |

6100 |

6800 |

|

|

C( mm) |

450 |

500 |

550 |

650 |

750 |

820 |

950 |

1200 |

|

|

D( mm) |

2100 |

2300 |

2500 |

2750 |

3100 |

3500 |

3800 |

4100 |

|

|

E( mm) |

500 |

550 |

600 |

700 |

1000 |

1200 |

1650 |

2200 |

|

|

F( mm) |

650 |

700 |

750 |

950 |

1100 |

1200 |

1300 |

1500 |

|

|

φa( mm) |

400 |

590 |

700 |

980 |

1380 |

1700 |

2300 |

3000 |

|

|

φb( mm) |

260 |

350 |

450 |

640 |

900 |

1100 |

1500 |

2000 |

|

Process flow chart

Options

Product charging by lifting machine.

Product charging by vacuum transfer system

Vibrating sifter

Automatic binder solution spraying system

Printer

WIP system

-

LZL Series Fluidized-vibrating And Continuous granulator

-

LZL Series Fluidized-vibrating And Continuous granulator

-

LZL Series Fluidized-vibrating And Continuous granulator

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow