DW Series Mesh Belt Dryer

DW Series Mesh Belt Dryer

Product Description

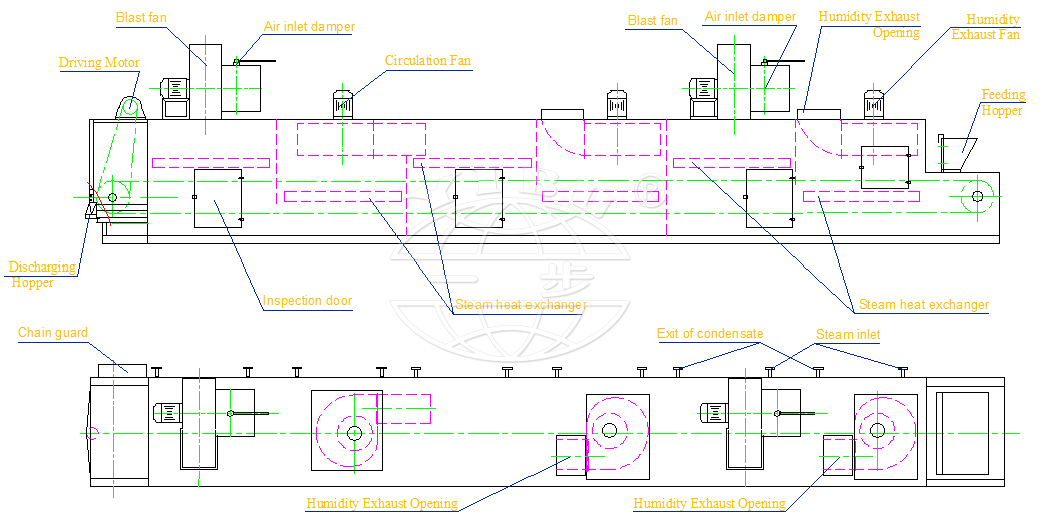

This machine is a continuous penetrating flow drying equipment applied for drying material in strip ,particle or slice state and with good ventilation.The machine is suitable for the materials such as DE-watering vegetable, herbal medicine of traditional Chinese medicine and others, for which the water contents are high and high drying temperature is not allowed. For our DW series mesh belt dryer , it is one of our main equipment and very hot machine in our company.there are two types of mesh belt dryer , one is for drying the material , the other is for cooling the material . The biggest difference between two machines are the mesh .

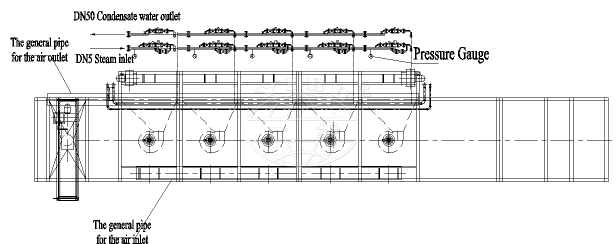

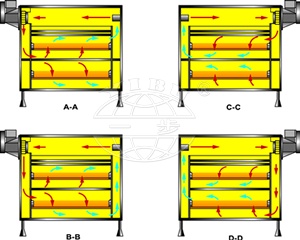

The materials are uniformly distributed on the mesh-belt by the material feeder. The mesh-belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device and move inside the dryer. The dryer is composed of several sections. For each section the hot air is circulated separately. Part of exhausted gas is exhausted by a special moisture exhaust blower. The waste gas is controlled by an adjustment valve. The hot air passes through the mesh-belt covered with bring water material away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material property. The final products after the drying process will fall into the material collector continuously. The top and low circulation units can be freely equipped according to client requirement;

1.High efficiency,low consumption and easy operation

2.No pollution,have heat insulating layer;fast heating,convenient to start and stop

3.The speed of mesh belt dryer could be controled

4.The temperature of the mesh belt dryer could be adjustable according to the buyer demands.

① Most hot air is circulated in the cabinet, heat efficiency is high and save energy.

② Use forced ventilation and cross flow type drying principle, there are air distribution plates in the cabinet and material is dried uniformly.

③ Low noise, stable operating, self-control temperature and convenience to install and maintain.

④ Wide scope of application, it is suitable for all kinds material, and is the general type drying equipment

⑤ Common control(Button control)or PLC and touch screen control are on request

⑥ Temperature controllable ;

⑦ Store memory of work-program mode and technological parameter and printing function (According to client’s requirements)

Single layer mesh belt dryer

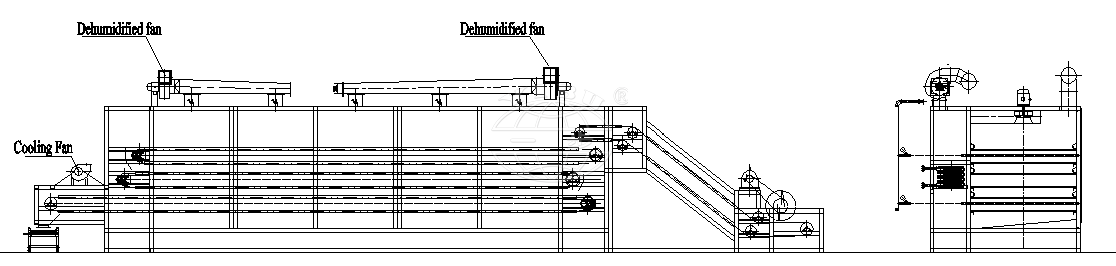

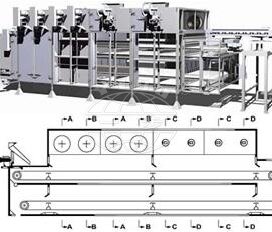

Multi-layer mesh belt dryer

Application

De-watering vegetable, particle feed, gourmet powder, shredded coconut stuffing, organic color, compound rubber, medicine product, medicine material, small wooden product, plastic product, aging and solidification for the electronic component and device..

|

spec |

DW-1.2-8 |

DW-1.2-10 |

DW-1.6-8 |

DW-1.6-10 |

DW-2-8 |

DW-2-10 |

|

unit number |

4 |

6 |

4 |

6 |

4 |

6 |

|

belt Width (m) |

1.2 |

1.2 |

1.6 |

1.6 |

2 |

2 |

|

drying section Length (m) |

8 |

10 |

8 |

10 |

8 |

10 |

|

Thickness of the material (mm) |

10-80 |

|||||

|

Temperature ℃ |

60-130 |

|||||

|

steam Pressure Mpa |

0.2-0.8 |

|||||

|

steam Consumption Kgsteam/KgH2O |

2.2-2.5 |

|||||

|

drying strength KgH2O/h |

6-20kg/m2.h |

|||||

|

total power of blower Kw |

3.3 |

4.4 |

6.6 |

8.8 |

12 |

16 |

|

total power of equipment KW |

4.05 |

5.15 |

7.35 |

9.55 |

13.1 |

17.1 |

Specialized machine for vegetable

|

|

unit |

three units series specialized machine for vegetable |

five layers specialized machine for vegetable(Frame type) |

|

|

model |

|

DWP-2-10-3 |

DWF-2-10-3 |

DW5-3-12 |

|

effective belt width |

m |

2 |

2 |

3 |

|

effective belt length |

m/unit |

10 |

10 |

12 |

|

tandemquantity |

|

3 |

3 |

|

|

layers |

|

|

|

5 |

|

vegetable capacity |

kg/h |

600 |

720 |

2000 |

|

evaporate strength |

kg/h |

400-510 |

480-640 |

1440-1800 |

|

consumption of steam |

Kgsteam/KgH2O |

2.2-2.5 |

2.2-2.5 |

2.2-2.4 |

|

heat radiation area |

m2 |

900 |

1440 |

2600 |

|

total power of the machine |

kw |

70 |

52 |

150 |

|

overall size |

m |

33.2×2.58×2.8 |

33.2×2.27×2.85 |

15.3×4.3×8.5 |

|

heat source type |

|

steam, theermal conductivity oil, hot air furnace, electric |

||

Specialized machine for feed (frame type)

|

Specialized machine for feed (frame type) |

||

|

model |

unit |

DWZ-3×12 |

|

effective belt width |

m |

3 |

|

effective belt length |

m/unit |

12 |

|

using temperature |

℃ |

80-130 |

|

pressure of steam |

Mpa |

0.4-0.8 |

|

drying time |

min |

35-50 |

|

thickness of material |

cm |

5-8 |

|

drying strength |

kg/h |

6-20 |

|

consumption of steam |

Kgsteam/KgH2O |

2-2.4 |

|

total power of the machine |

kw |

76 |

|

overall size |

m |

15.1×4.3×3.4 |

-

DW Series Mesh Belt Dryer

-

DW Series Mesh Belt Dryer

-

DW Series Mesh Belt Dryer

-

DW Series Mesh Belt Dryer

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow