JCT Series Special Drying Oven

JCT Series Special Drying Oven

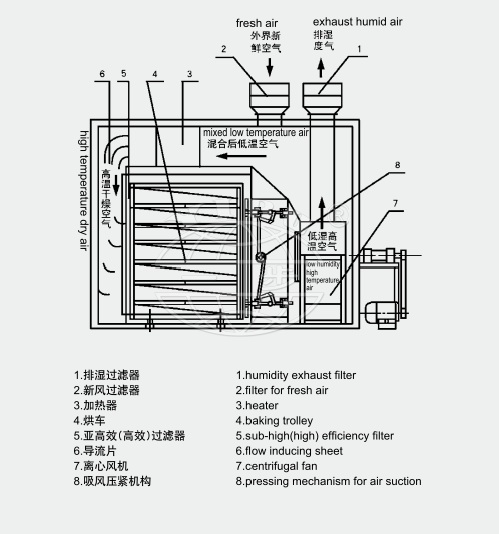

Principle

The air steam passes through only the surface of raw material in traditional chamber drier. The disadvantage is that the coefficient of raw material only in traditional level chamber dryer. The disadvantage is that the coefficient of heat transfer is low, the drying time is long, and it has defects in structure, can not be in conformity with the requirements of "GMP". In order to over-come the shortage, we designed and developed the penetrating air stream chamber dryer on the basis of absorbing foreign advanced technology. The principle of work is shown in the diagram below.

The fresh air is sucked by fan and then filtered by pre, post and sub-high efficiency to achieve 10,00 grade clean effect. Pass through steam heat exchanger the temperature of air rises to certain temperature. The heated air passes through flow distributor enters every layer, passes through each layer of raw material to be dried, humid air is exhausted through the inclined air channel under the drying tray. Part of the air circulates in the system.

Feature

1.To avoid pollution of product caused by circulation air, all circulation air passes through post or high efficiency filters. It is in conformity with the requirements of GMP.

2.Compared to traditional horizontal chamber dryer, its capacity of drying is larger. The thickness of raw materials each layer can be over three times.

3.Compared to traditional horizontal chamber dryer, its drying area is large and its efficiency is high. Its capacity of drying might be several times higher, the cost is reasonable.

4.Applicable to dry various kinds of granules and block of materials.

5.Easy in operation, convenient in parts exchanging, low in faults.

6.There are air filters at air inlet and air outlet. Therefore the dried raw materials can’t be polluted and the quality of product can’t be effected.

7.The hot source can adopt steam , oil or electric heater.

Flow Chart

Application

This drying oven is suitable for material and product hot solidification and dry de-watering in the pharmaceutical, chemical, food, farming side-product, aquatic product, light industries, heavy industries and others industries. Such as: raw material medicine, crude drug, prepared herbal medicine of Chinese traditional medicine, plaster, powder, particle, drinking agent, pill, packing bottle, pigment, dyestuff, dewatering vegetable, dried fruit piece, sausage, plastics, resin, electric component, baking varnish and etc.

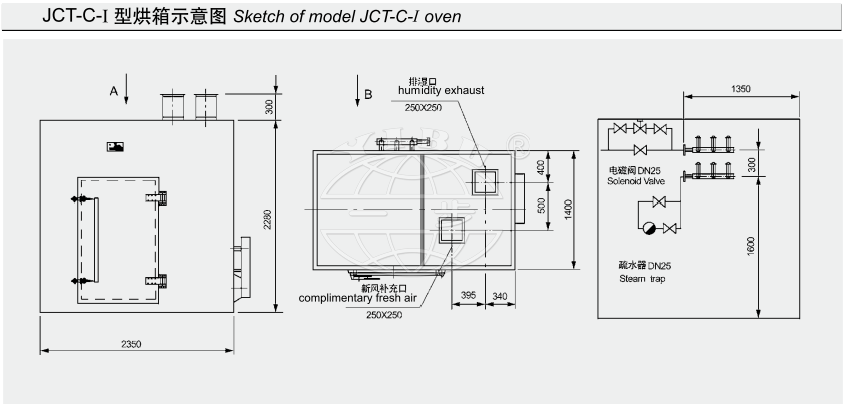

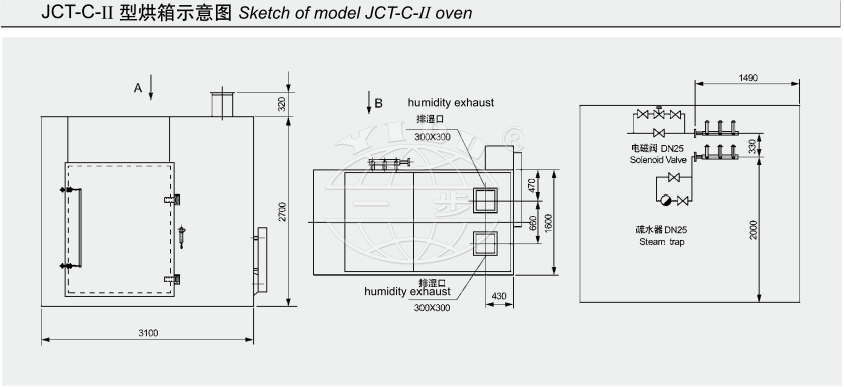

Installation drawing

Technical parameters

|

item spec |

dry amount of each batch |

power |

steam consumption (kg/h) |

area of heat(㎡) |

amout of air |

temperature difference between up and low |

size of drying tray |

quantity drying tray |

overall dimensions |

weight |

| JCT-C-I | 100 | 4 | 40~80 | 50 | 4000~7300 | ±2 | 550*610*80 | 10 | 2350*1400*2280 | 2200 |

| JCT-C-II | 200 | 7.5 | 80~120 | 80 | 7200~15800 | ±2 | 530*610*80 | 20 | 3100*1600*2700 | 4000 |

| materials(kg) | catalyst | pharmceutical | catalyst | resin | product of kiln | amino acid | ||

| capacity(%) | 200 | 260 | 370 | 350 | 100 | 200 | ||

| initial moisture(%) | 60 | 65 | - | 35 | 31 | 50 | ||

| mass density(kg/L) | 0.3 | 0.5 | - | 10 | 3 | 2 | ||

| temperature of hot air (℃) | 0.56 | 0.5 | 0.92 | 0.8 | 0.51 | 0.5 | ||

| drying time(h) | 60 | 80 | 400 | 150 | 100 | 80 | ||

| drying area(㎡) | 5 | 6 | - | 3 | 40 | 1 | ||

| heat source | 6.5 | 5.3 | 4.6 | 6.3 | 6.6 | 6.6 | ||

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow