Advanced Granulation Technology(11)

Discussion

With increasing emphasis on reduction or elimination of serum from media formulations leading to increasingly complex biochemical composition (6,7) for biopharmaceutical production applications, issues such as trace component homogeneity, additions of components not suitable for inclusion in standard powder milling, and minimization of aerosoled powders for facility hygiene become more significant. Typically, dissolution of powder medium is slow and requires subsequent addition of sodium bicarbonate and various other biochemical components or concentrated solutions. Further, the reconstituted media must be titered to the correct pH and/or osmolality after addition and dissolution of all components.

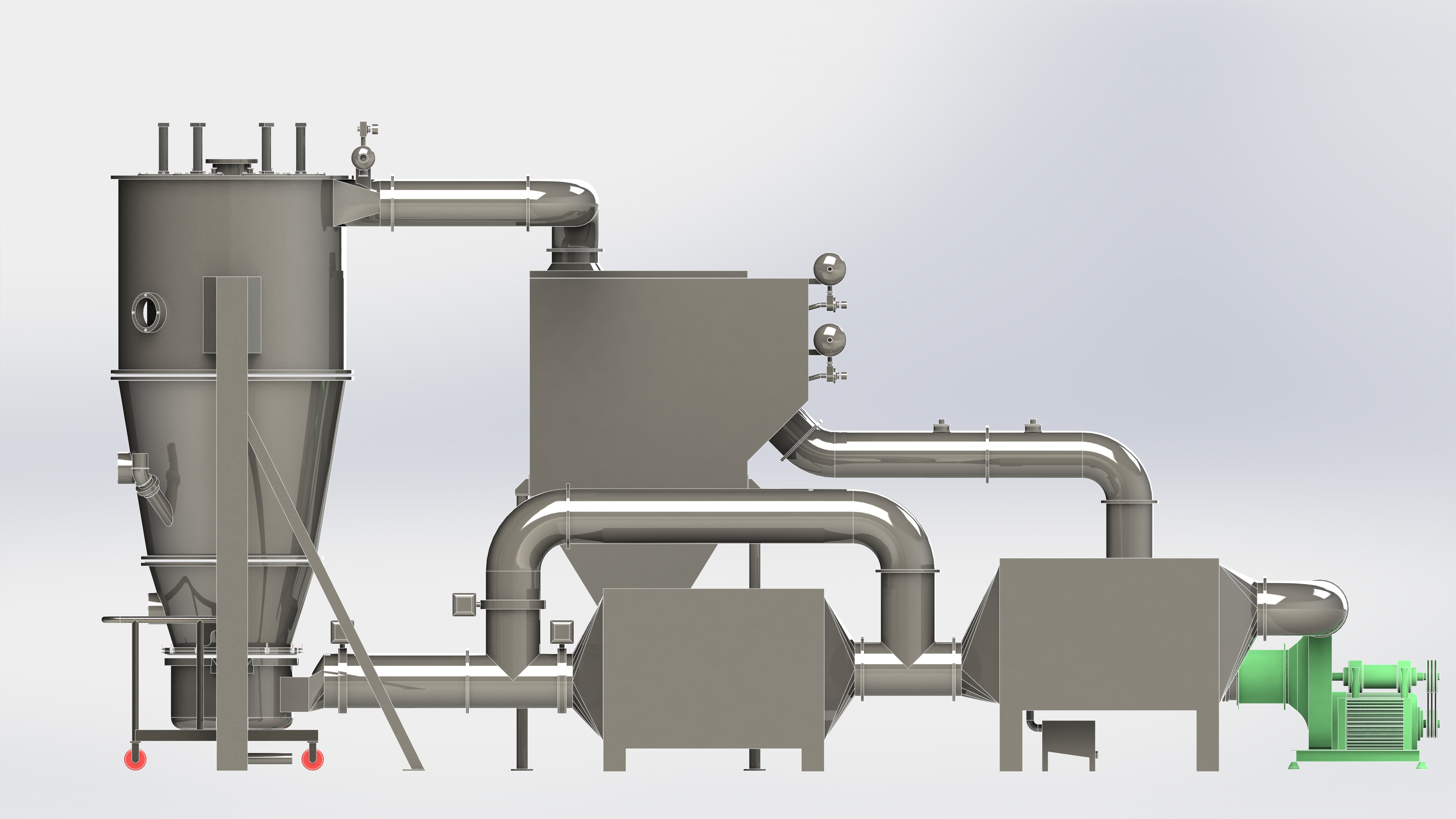

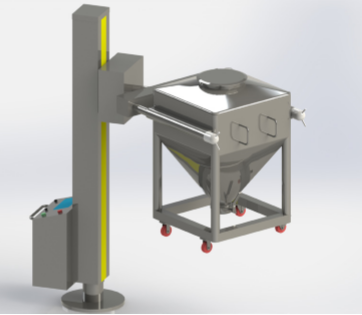

We have developed a process to manufacture a complete, dry format, cell culture media and demonstrated its homogeneity and acceptable performance at various production scales. The characteristics of this novel medium format may be advantageous for biopharmaceutical applications where minimal manipulation of powder media during reconstitution may result in fewer errors, higher media throughput and less variability in final product. We previously reported bench scale (2kg) production of several serum-free and protein-free AGT single component granulated media and demonstrated that this format significantly alleviated these constraints (3). We here report successful scale up of AGT CD-CHO to 500 kg as evidenced by homogeneous biochemical component distribution, cell culture growth and β-galactosidase production. CD-CHO medium was selected for initial scale up, although other formulations also should be directly scalable to the 500kg level since our process development was performed in scalable fluid bed processors. (Studies to date with other serum-free formulations from bench scale to the 9kg level confirm this extrapolation, data not shown).

The maximum weight of granulated material processed in a single run (500kg) using production-scale fluid bed processors compares favorably with the manufacturing scale of a typical large scale ball mill (~300kg). In addition, we have demonstrated homogeneous blending of multiple batches of AGT-based media in standard mixing equipment. A typical large blender may hold up to ~4500kg of material, depending upon density of specific formulations. Assuming that a serum-free formulation is reconstituted at 20g/l, then the single lot capacity of this blender (~4500kg) would represent 225,000 liter-equivalents of medium.

There are additional advantages for use of the AGT technology compared to ceramic ball milling technology. Both the particle size reduction and the granulation processes are performed in 316L stainless steel units, facilitating equipment cleaning and sanitization by validated procedures. We have demonstrated significant (greater than 4 log) reduction of challenge panels of model viruses and prison elements using appropriate sanitization protocols (8). Further, the total capacity of the AGT process, the individual fluid bed productions coupled with blending technology, is equal to or greater to than standard ball milling capacity. The AGT process delivers nutrient formulations that are biochemically indistinguishable from ball-milled DPM counterparts. From a biological performance perspective, the decreased processing time, reduced physical impact, and more-controlled (lower) operating temperature associated with the AGT process have resulted in serum-free dry-format media with quantitative improvements in biological performance (e.g. cell growth, productivity).

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow