Pneumatic dry granulation(4)

Source: | Date:

2011-11-03

| Hits:

Keywords:

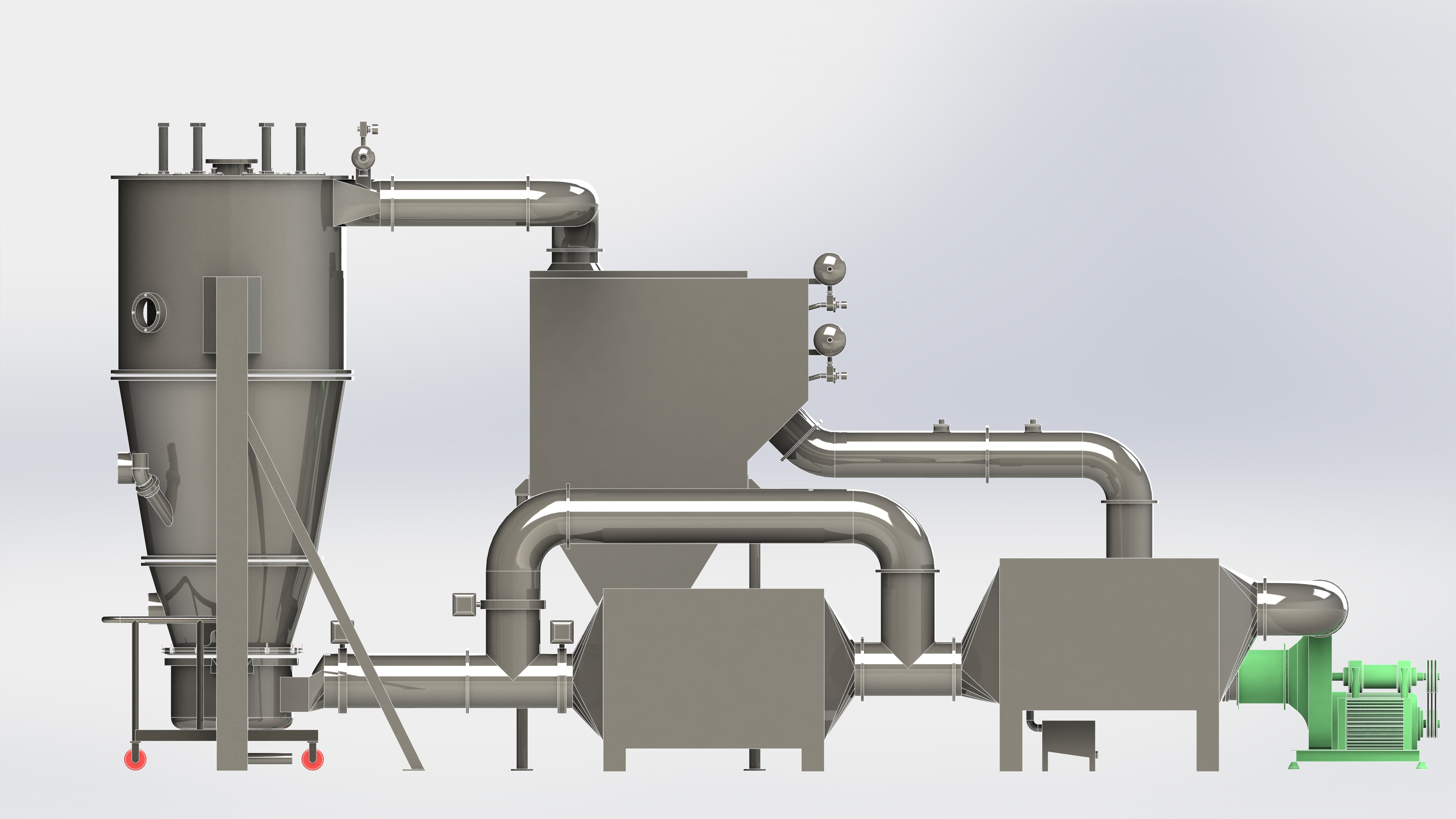

RC is a continuous dry granulation process with the aim of manufacturing free flowing granulate, increasing the bulk density and ensuring the uniformity of particulate formulations by preventing the segregation of the constituents of the

powder. In RC, a powder blend is compacted between two counter-rotating rolls. In the narrow region of the gap between the rolls, the powder is subjected to pressure, leading.

This ribbon is then reduced in size using dry milling to achieve the desired granule size. The main purpose is to obtain granulate with acceptable flow properties and sufficient secondary compactibility for the subsequent processing steps, typically tableting or encapsulation. The theory of compaction and RC is not covered in this review but provided elsewhere [3,5]. Successful use of RC has been demonstrated in the development and production of conventional immediate release solid dosage forms [6-9] as well as for controlled release drug delivery systems.

News

- 2024-06-08 > Exhibition Invitation |ACHEMA 2024, Germany

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

Products